Sorry I haven't been as active as I should have been for a while. Maye this will make up for it a little bit.

I started making this in the summer of last year. I made the crankcase from 4 pieces of aluminum.

I got the idea from a post by "nemt" on HMEM.

I used J-B weld to glue it together along with the screws.

The heads are 2 piece to make the water passages as this is a water cooled engine. They will be glued together also. They still have to be profiled to the cyl contours yet.

I was sweating bullets about making the crankshaft but it wasn't all that bad! I used some hot rolled steel and left it about .030 oversize and rested it for a few days before I finished it to size. I still have to thread both ends yet but it is true.

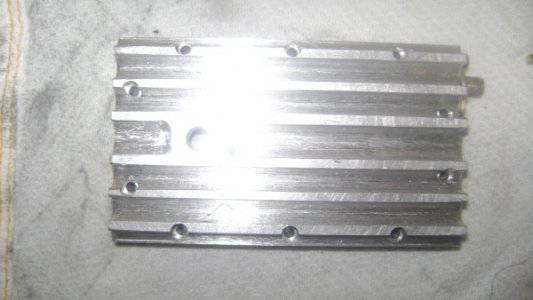

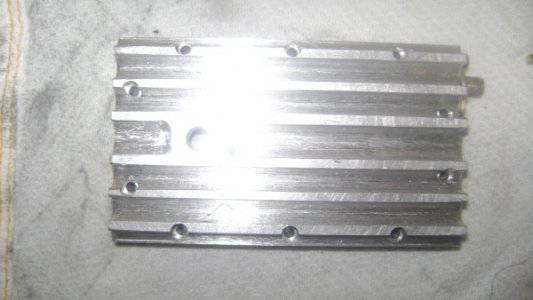

This is the top of the crankcase. The hole is to put the oil in and the raised pad is for mounting the carb or carbs as you can use 2 if you want.

This is the bottom of the oil pan or sump if you will. Sorry about the bad pic.

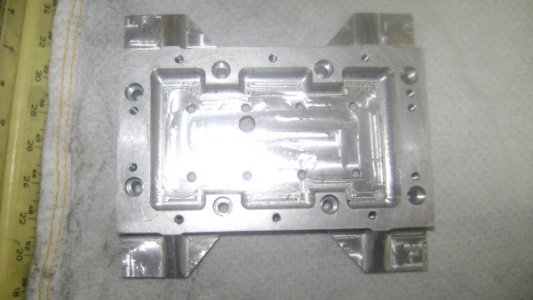

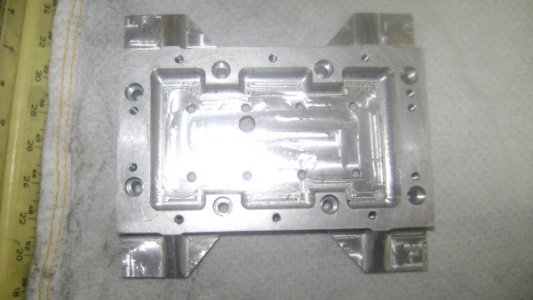

This part goes between the oil pan and the crankcase and has the engine mounting pads on it. How ever I goofed up and machined the mounting pads up side down. The will still work but it's not plan.

More to come.

Ron

I started making this in the summer of last year. I made the crankcase from 4 pieces of aluminum.

I got the idea from a post by "nemt" on HMEM.

I used J-B weld to glue it together along with the screws.

The heads are 2 piece to make the water passages as this is a water cooled engine. They will be glued together also. They still have to be profiled to the cyl contours yet.

I was sweating bullets about making the crankshaft but it wasn't all that bad! I used some hot rolled steel and left it about .030 oversize and rested it for a few days before I finished it to size. I still have to thread both ends yet but it is true.

This is the top of the crankcase. The hole is to put the oil in and the raised pad is for mounting the carb or carbs as you can use 2 if you want.

This is the bottom of the oil pan or sump if you will. Sorry about the bad pic.

This part goes between the oil pan and the crankcase and has the engine mounting pads on it. How ever I goofed up and machined the mounting pads up side down. The will still work but it's not plan.

More to come.

Ron