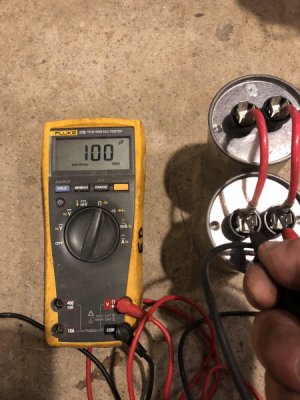

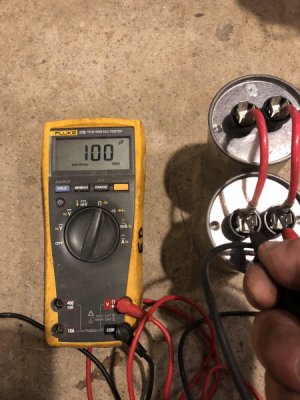

Thanks for the responses. I opened up the enclosure and found only 2 capacitors inside, there are no markings on them but they both tested to 50 microfarads, so 100 uF total, I assume they are okay.

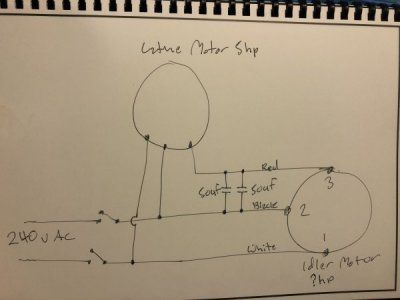

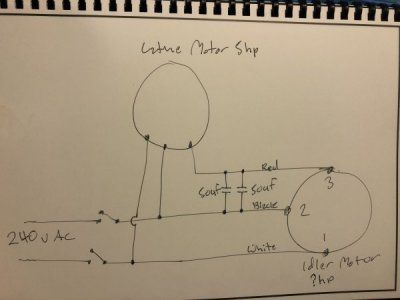

After reading up on info I found around the net, it appears the converter is wired in a simple "self starting" configuration. This is how its wired.

The Info I read says the capacitor value should be 25-30 uF per hp for a self start circuit so that would mean the idler should only be 4hp max (there is no spec plate on the idler), which doesn't make sense as the spec plate says it can, and does, start a 5 hp motor and according to what I've been reading the idler should be twice the hp of the maximum motor to be started?

So I first assumed increasing the capacitor values might help, but then I read, increasing the caps will increase the voltage which is already looking kind of high?

Line voltage, Between L1-L2, 246.1 no load, 243.4 with the idler and lathe motor, load.

Between L2-L3, 273.3v no load, 240.7v w/load.

Between L1-L3, 251.1v no load, 225.6v w/load.

Being this is my first foray into Rotary Phase Converters, I am not sure how I should go about tuning this contraption, do I increase or decrease the caps or do I rewire the whole thing to a more advanced configuration?

The lathe is very quiet so this RPC is too noisy to use as is. Even under load, it is quite annoying. I am also not too keen on using a VFD for this lathe (I have them on other machines) as I don't need the variable speed option, I would need a 2nd VFD for the coolant pump and I don't want to have to rewire all the controls...

I appricheate your thoughts,

Eddy