- Joined

- Jan 3, 2015

- Messages

- 400

I've been working with my rotary table for CNC G0704 mill system and can't get past an issue. I can't seem to get the table's center of rotation under my spindle.

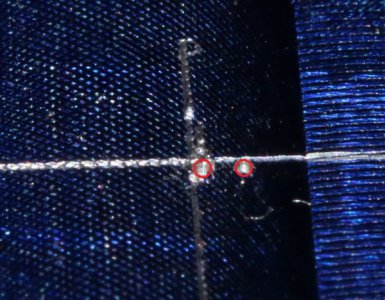

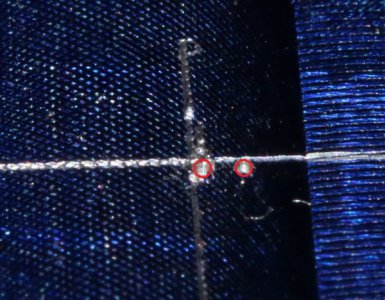

The table is a 6" RDX table from Wholesale Tool, which seems to be fairly popular.

When I first stumbled on the issue, I was putting a piece of stock with layout lines scratched in Dykem under a pointy center finder. I set up the long dimension of the part to parallel my X axis, set as 90 degrees on the table, and then I would line up the point over one line, rotate the table 90 degrees (to 180) and line up the point over the other line. I went back and forth between 90 and 180 until the center where the lines crossed was under the center of my spindle. At one point, I decided to rotate the table completely. As I went past 270, I could see the point was no longer over the place where the lines cross. Same when I got to zero degrees (360). I marked the points with the center finder and measured between them. They were close to 0.032 apart. (Two holes marked in red to help you see them - when I laid the calipers over them, they were about that far apart, center to center. )

So I took off my work and switched to a DTI I have that measures with .0005" marks. I found the X coordinate for both edges of the hole and then repeated for Y. When I was done, I could set X or Y to the same numbers, + or -, and the DTI would indicate the same thing for the edges, within that .0005. So for both X and Y, 0.000 is the center of the MT2 taper in the table. Then I clamped a piece of thin aluminum to the table and using the finest engraving bit I have (which has a .010 tip) found that it cuts a circle that's about .035 in diameter (center of the path, not the very edges - those are about .050.

Again, it seems like the center of rotation of the table is not the physical center of the table. I didn't know that was possible.

Is this common?

How would I find the center of rotation, so I could put it under the center of the spindle? Is there anything else I can do?

The harder question is whether it matters to my project. I'm just starting out building one of the Philip Duclos flame eater engines. Since I'm not machining parts that have to match another exactly, I'm guessing no. This is cutting the outside profile of a support for the engine. The center of this will be cut with a boring head to match the diameter of the cylinder.

Bob

The table is a 6" RDX table from Wholesale Tool, which seems to be fairly popular.

When I first stumbled on the issue, I was putting a piece of stock with layout lines scratched in Dykem under a pointy center finder. I set up the long dimension of the part to parallel my X axis, set as 90 degrees on the table, and then I would line up the point over one line, rotate the table 90 degrees (to 180) and line up the point over the other line. I went back and forth between 90 and 180 until the center where the lines crossed was under the center of my spindle. At one point, I decided to rotate the table completely. As I went past 270, I could see the point was no longer over the place where the lines cross. Same when I got to zero degrees (360). I marked the points with the center finder and measured between them. They were close to 0.032 apart. (Two holes marked in red to help you see them - when I laid the calipers over them, they were about that far apart, center to center. )

So I took off my work and switched to a DTI I have that measures with .0005" marks. I found the X coordinate for both edges of the hole and then repeated for Y. When I was done, I could set X or Y to the same numbers, + or -, and the DTI would indicate the same thing for the edges, within that .0005. So for both X and Y, 0.000 is the center of the MT2 taper in the table. Then I clamped a piece of thin aluminum to the table and using the finest engraving bit I have (which has a .010 tip) found that it cuts a circle that's about .035 in diameter (center of the path, not the very edges - those are about .050.

Again, it seems like the center of rotation of the table is not the physical center of the table. I didn't know that was possible.

Is this common?

How would I find the center of rotation, so I could put it under the center of the spindle? Is there anything else I can do?

The harder question is whether it matters to my project. I'm just starting out building one of the Philip Duclos flame eater engines. Since I'm not machining parts that have to match another exactly, I'm guessing no. This is cutting the outside profile of a support for the engine. The center of this will be cut with a boring head to match the diameter of the cylinder.

Bob