U

umahunter

Forum Guest

Register Today

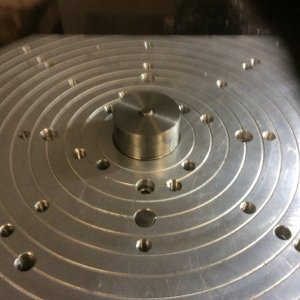

I would like to make this lil tool like in Tom's techniques video. it's basically a lil taper on a dowel pin you bring down into the center hole to get you very close to center. what I'm wondering is can I cut a short 1 inch long(not even sure it needs to be that long ) mt2 taper with my compound on my G0602 10x22 lathe by setting to a certain degree instead of trying to turn between centers and trying to offset the tailstock etc. lol since I'm still recovering from back surgery I'm trying to take the fastest route to get the job done without having to remove my chuck etc. just trying to figure if it can be done this way or it I'm setting myself up for frustration also if it can be done anyone know what degree an mt2 taper is ??? Thanks for any help  here's Tom's video https://www.google.com/url?q=https:...DfMQwW4IHDAD&usg=AOvVaw1M1gpexKVKDdiHptKVf5n2

here's Tom's video https://www.google.com/url?q=https:...DfMQwW4IHDAD&usg=AOvVaw1M1gpexKVKDdiHptKVf5n2