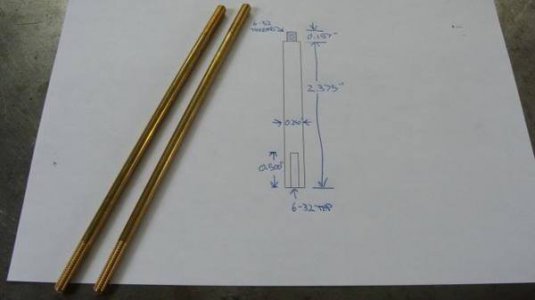

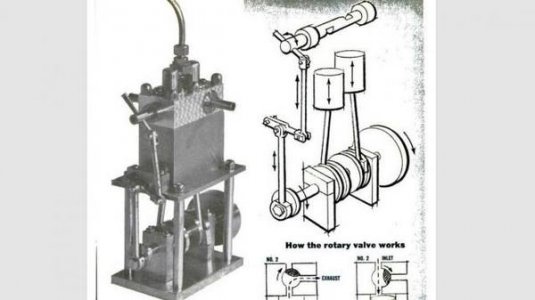

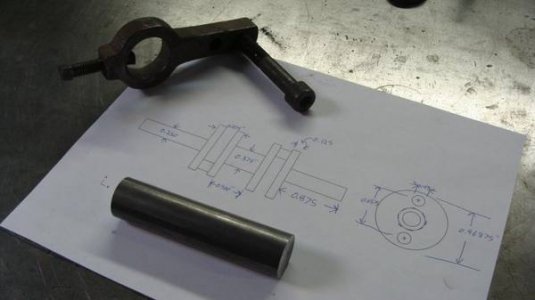

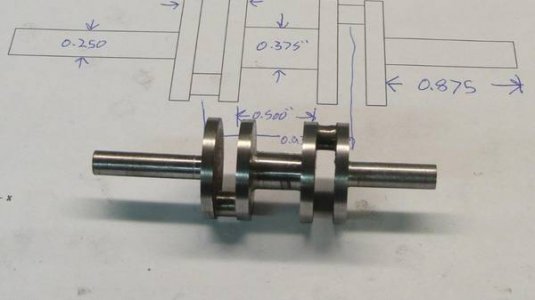

This is my first steam engine, so I went with one that didn't involve casting parts or machining gears. This one is published in the December 1961 issue of Popular Science. It has about 30 parts, all starting from easy to get steel, aluminum, and brass/bronze stock. I decided to start with the hardest part, the crankshaft. I took the original dimensions(in fractions) and made up a cad drawing to print out. This piece needed a 1"x4" steel rod.

After facing off the ends, I used a locking v-block to scribe in the center and outer lobes.

I've only used a cutoff tool in the lath a few times. The distance between the lobes are only 3/16" so there isn't many choices. I went at it slow and steady, cutting each one a bit at a time.

Once those were cut, it was much easier to remove the rest of the material.

Here is the finished product, before final sand and polishing:

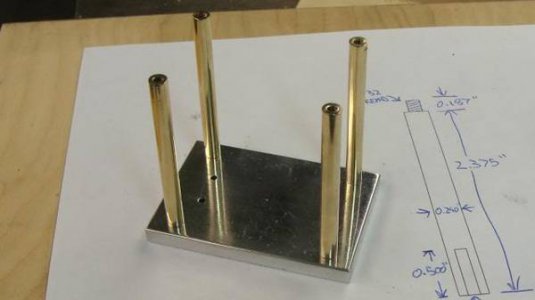

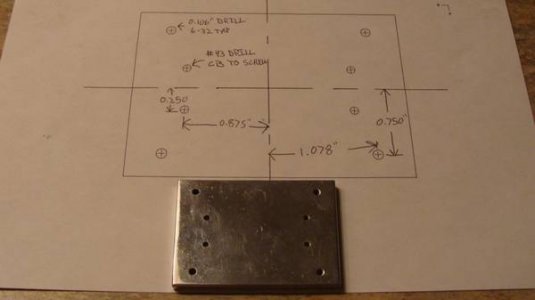

I had about 5 hours of lathe work on this piece. I had some time today to get another piece of the puzzle done, the base made out of 1/4" aluminum.

I'm hoping to get a few parts done here and there and updating often. I'm always open to questions, opinions, or if there was an easier way of doing things. I'll try to get a few pics of the machines I'm using as well. As being my 2nd post, I'm not sure if off site photo hosting is frowned upon or not. It's a bit easier for me to keep things organized. Thanks, Joe