-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Round stock center locator

- Thread starter mirage100

- Start date

Do you mean something like this?

www.micromark.com

www.micromark.com

Center Square, 2-1/2 Inch Capacity

DetailsLocate the Center of Your Workpiece Without Complex Calculations Find the center of the workpiece quicklyUse to find center for round, square and octagonal parts up to 2-½ inchesMade of precision ground steelFind the center without complex calculations

- Joined

- Nov 26, 2015

- Messages

- 4,762

Plenty for sale on Ebay.

Center Finder Head With Nice12 Inch Rule USA Made Four Graduations | eBay

It looks like Brown & Sharpe, but I cannot find any maker's marks on either the center finder or rule.

www.ebay.com

- Joined

- Oct 4, 2016

- Messages

- 7,000

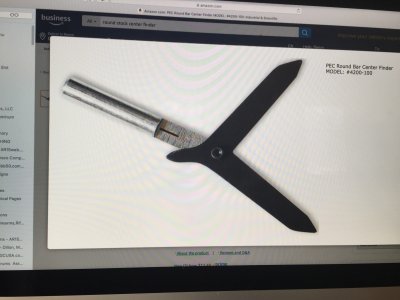

If your on the length there's this type.

One of the youtube gurus has another method. Face, and drill a short piece of your stock, part it off, put the length in a vice, lay the disc with the hole in it on top for the length where you wish to mark, then transfer punch it...

Amazon.com: PEC Round Bar Center Finder MODEL: #4200-100 : Tools & Home Improvement

Amazon.com: PEC Round Bar Center Finder MODEL: #4200-100 : Tools & Home Improvement

www.amazon.com

One of the youtube gurus has another method. Face, and drill a short piece of your stock, part it off, put the length in a vice, lay the disc with the hole in it on top for the length where you wish to mark, then transfer punch it...

- Joined

- Dec 6, 2015

- Messages

- 807

I'd do a bell-mouthed center punch, similar to :

https://www.amazon.com/Center-Punch-Marks-Exact-Round/dp/B07NRJ6691/ref=sr_1_6

Here's a quick how-to on using one :

Mr. Pete on youtube did a little mini-series on making one of these, and if my memory serves me, there was a "machine shop projects" variant in the old high school shop days for it. Here's mr pete's first video if you have a lathe and want to make one :

https://www.amazon.com/Center-Punch-Marks-Exact-Round/dp/B07NRJ6691/ref=sr_1_6

Here's a quick how-to on using one :

Mr. Pete on youtube did a little mini-series on making one of these, and if my memory serves me, there was a "machine shop projects" variant in the old high school shop days for it. Here's mr pete's first video if you have a lathe and want to make one :

- Joined

- Feb 17, 2013

- Messages

- 4,406

Do you have the round stock standing up on end, or lying down along its side?

If standing on end - Eyeball the approximate center. Use a center finder in the X direction to find the edges, set zero halfway between, and move the table in X to that position. Now repeat the process in the Y direction. To refine/verify the X position of the center point, repeat the X procedure with the table at Y zero.

If lying on its side - For a "pretty good" center (assuming it's centerline is oriented in the X direction; change procedure as needed if the axis is lined up with Y), I use a device like the one @mirage100 posted ... but I do the "measurement" in four different ways, noting the Y position each time, then use the average of the four. The four ways: 1. Set up the indicator with the table a bit "forward" of center. Move Y from the front to the back, noting when the marks are lined up. 2. Repeat this, starting with the indicator "behind" center. 3. Raise the spindle, rotate the indicator 180º, repeat step 1. 4. Repeat step 2. The two marks you're trying to line up visually are probably something like 0.020" wide, so perfect alignment can be difficult. By doing the 4 measurements and averaging, you minimize the error.

If lying on its side - For an "exact" center, use a 1/2" diameter center finder, like

and touch off each side at its widest point (ie, along the horizontal diameter); set zero halfway between.

If standing on end - Eyeball the approximate center. Use a center finder in the X direction to find the edges, set zero halfway between, and move the table in X to that position. Now repeat the process in the Y direction. To refine/verify the X position of the center point, repeat the X procedure with the table at Y zero.

If lying on its side - For a "pretty good" center (assuming it's centerline is oriented in the X direction; change procedure as needed if the axis is lined up with Y), I use a device like the one @mirage100 posted ... but I do the "measurement" in four different ways, noting the Y position each time, then use the average of the four. The four ways: 1. Set up the indicator with the table a bit "forward" of center. Move Y from the front to the back, noting when the marks are lined up. 2. Repeat this, starting with the indicator "behind" center. 3. Raise the spindle, rotate the indicator 180º, repeat step 1. 4. Repeat step 2. The two marks you're trying to line up visually are probably something like 0.020" wide, so perfect alignment can be difficult. By doing the 4 measurements and averaging, you minimize the error.

If lying on its side - For an "exact" center, use a 1/2" diameter center finder, like

and touch off each side at its widest point (ie, along the horizontal diameter); set zero halfway between.