- Joined

- Nov 26, 2012

- Messages

- 1,307

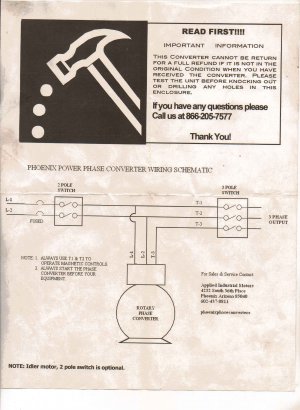

I had an rpc in the past that was so quiet that I had to remember to shut it down. I now have a 3 hp phoenix phase converter and it is very loud. Is it just poor quality? should I add caps to the run circuit? I actualy don't think it has a seperate start and run circuit.

Have you had any dealings with these? Did they just compromise on capacitors using start caps full time?

It has no contactor or relays.

Have you had any dealings with these? Did they just compromise on capacitors using start caps full time?

It has no contactor or relays.