- Joined

- Jan 2, 2014

- Messages

- 8,851

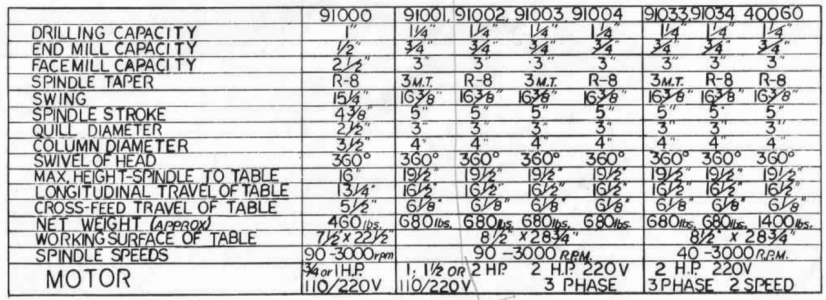

I do not know exactly what the spindle taper number is/means, that will determine my model.

You will need to know this. It determines what tooling you can use.

The R8 taper collets looks like this:

https://littlemachineshop.com/products/product_view.php?ProductID=5915&category=

MT-3 taper collets look like this:

https://littlemachineshop.com/products/product_view.php?ProductID=1948&category=

Both kinds use a draw bar that's threaded into the back end to hold them into the spindle.

If you got any tooling with the machine, compare it to the pictures above.

Brian

.

.