- Joined

- Jan 28, 2019

- Messages

- 62

Long post here.

I'm a hobby bicycle frame builder (for about 40 years), local bike shop wrench (for 45 years including a 15 year stint as an owner) and boarding on retirement. I've decided to grow my frame shop (basement and garage) recently with larger tools. One is an 8x30 mill with the brand Sampson". It's well used and been through a few hands if I had to guess. I bought it a five years ago and only got to working with it three years ago. My one year of tool and die in 1982 was a long time ago...

First a thanks to Z2V for the link to the Grizzly mill, G0730/1, that sure looks to be the same basic machine. This has allowed me to look at a few aspects that I had wondered about.

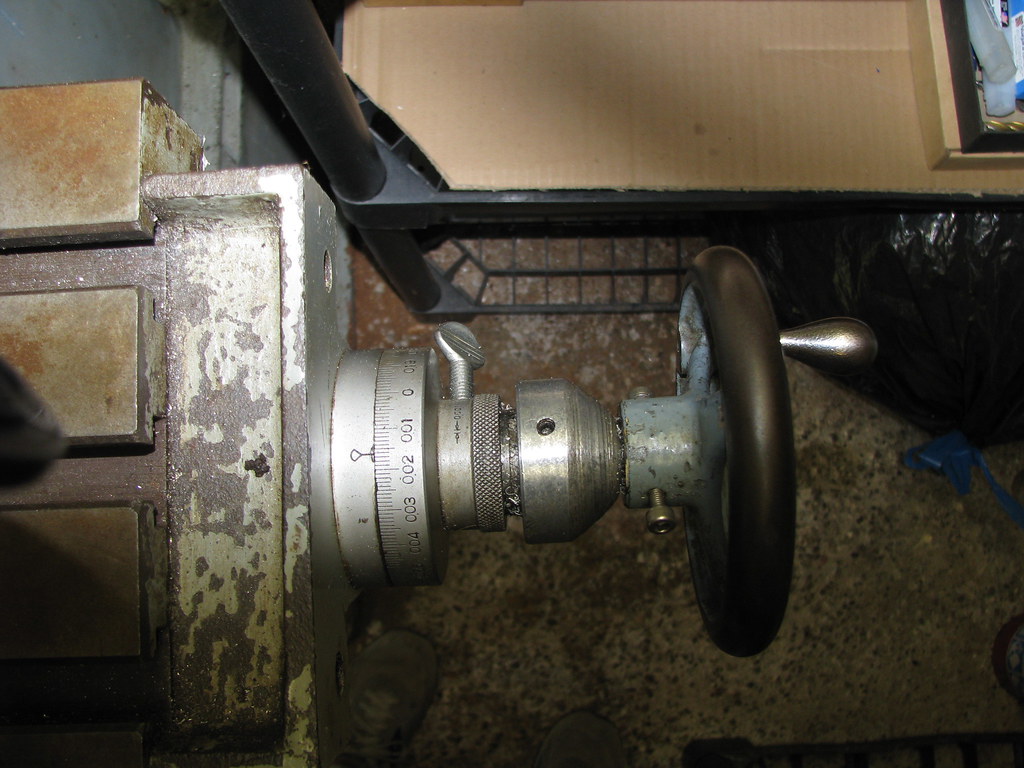

- My mill suffers from about half a rotation of the hand crank's free play on the Y travel. If I understand correctly I need to access the saddle travel half nut to tighten this. But to get to this half nut it looks like I have to remove the table first then the saddle. Is this correct? Or is there another point of access?

_ The mill's "rubber" chip cover is missing. Looking at the Grizzly parts diagrams and my mill I note similar mounting holes for this cover. Thoughts? I suspect these kinds of parts are rather non specific.

- The mill has been used a fair amount without this cover, given the amount of crap down in the saddle I see. At some point I would like to clean it all out (my bicycle servicing standards "first clean then make better".) Removing the table would make this cleaning far easier and likely more complete. How much does the table weigh?

I'll read up the Grizzly manual and make some plans, parts needs. Soon it will be bike repair season (and riding too) so I suspect it will be a while before I dive into my mill. When I do I'll have more questions, that's for sure. Again thanks for the help. Andy

I'm a hobby bicycle frame builder (for about 40 years), local bike shop wrench (for 45 years including a 15 year stint as an owner) and boarding on retirement. I've decided to grow my frame shop (basement and garage) recently with larger tools. One is an 8x30 mill with the brand Sampson". It's well used and been through a few hands if I had to guess. I bought it a five years ago and only got to working with it three years ago. My one year of tool and die in 1982 was a long time ago...

First a thanks to Z2V for the link to the Grizzly mill, G0730/1, that sure looks to be the same basic machine. This has allowed me to look at a few aspects that I had wondered about.

- My mill suffers from about half a rotation of the hand crank's free play on the Y travel. If I understand correctly I need to access the saddle travel half nut to tighten this. But to get to this half nut it looks like I have to remove the table first then the saddle. Is this correct? Or is there another point of access?

_ The mill's "rubber" chip cover is missing. Looking at the Grizzly parts diagrams and my mill I note similar mounting holes for this cover. Thoughts? I suspect these kinds of parts are rather non specific.

- The mill has been used a fair amount without this cover, given the amount of crap down in the saddle I see. At some point I would like to clean it all out (my bicycle servicing standards "first clean then make better".) Removing the table would make this cleaning far easier and likely more complete. How much does the table weigh?

I'll read up the Grizzly manual and make some plans, parts needs. Soon it will be bike repair season (and riding too) so I suspect it will be a while before I dive into my mill. When I do I'll have more questions, that's for sure. Again thanks for the help. Andy