Hi Gents

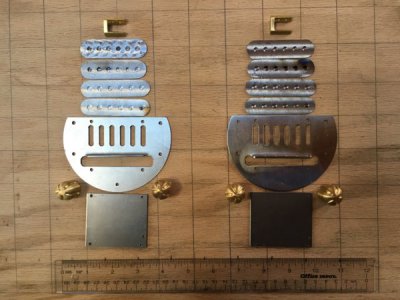

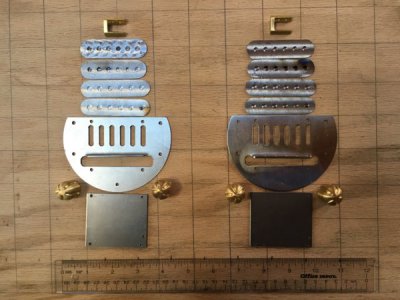

What’s the most efficient way to sand steel? I found a nickel plater for my parts and he said that if I want a mirror finish that the parts need to be sanded and polished to a mirror finish. I started doing this today via running the part over wet/dry 320 grit. It’s taking forever to get the end mill/facing marks out.

Is there a better/quicker/easier method for the sanding process?

What’s the most efficient way to sand steel? I found a nickel plater for my parts and he said that if I want a mirror finish that the parts need to be sanded and polished to a mirror finish. I started doing this today via running the part over wet/dry 320 grit. It’s taking forever to get the end mill/facing marks out.

Is there a better/quicker/easier method for the sanding process?