- Joined

- Feb 2, 2013

- Messages

- 3,622

I started a woodworking project on the Unimat SL1000.

After a couple sample turnings, I decided the Unimat was too valuable to sacrifice to wood dust.

Instead I decided to wreck a cheap woodturning lathe instead of the Unimat

Enter the cheapest woodturning lathe i could find on Amazon, The Sanjiang 100watt (at24vdc) Mini lathe

it came with an adjustable power supply 12-24vdc, some basic tools, an affixed drill chuck, a crudely adjustable tailstock , and a 45mm tool rest, some very inexpensively designed and made turning tools (throw these tools out unless you are going to be turning objects the magnitude of strength of a toothpick, they are poorly made turning tools- but really, what do you want though for $38???? )

after turning a sample piece in softwood (pine), i decided the lathe was in desperate need of modification.

the power was sufficient, but the spindle speed at 24vdc was way too fast for my taste

i ran through the available voltage selections, taking cuts with each.

running it on the 12vdc setting dropped the available torque, but brought the spindle speeds to workable levels

the lack of a finely adjustable tailstock meant that work needed to be held in the chuck or held by screw mandrel -

a spur drive center worked but , the lack of a tailstock screw adjustment made pressure turning sketchy at best

i decided to remove the existing tailstock and install a purchased adjustable tailstock assembly

i screwed up the vertical clamp on the purchased tailstock by knocking off too much material, trying to get the center height right.

shims were unacceptable.

i decided to reproduce the vertical clamp

some scrap 6061, was used

in the BP mill i roughed out the basic size

left: original tailstock clamp , center: clamp billet , right: purchased adjustable tailstock

i got the basic form and used the original tailstock platform to drill a dimple to get the correct center height.

i transferred the billet to the Unimat for drilling the pilot hole

i drilled the center to 5/8", reamed to 16mm to accept the tailstock capsule , cross drilled to 4mm

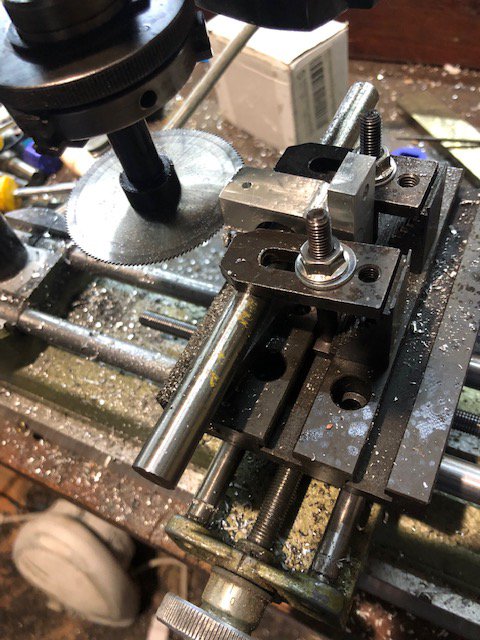

i returned the clamp to the Unimat for slitting with a precarious set up

after slitting, i drilled one half of the clamp to 5.5mm, tapped the other side to 5mm, and installed a clamp bolt

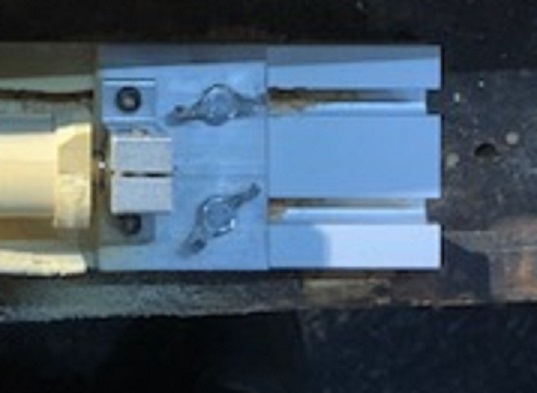

i drilled and tapped the base of the tailstock to accept the retrofit adjustable tailstock, swapped out wing nuts for round head hex screws

i installed the adjustable tailstock quill into the clamp block and set the projection

After a couple sample turnings, I decided the Unimat was too valuable to sacrifice to wood dust.

Instead I decided to wreck a cheap woodturning lathe instead of the Unimat

Enter the cheapest woodturning lathe i could find on Amazon, The Sanjiang 100watt (at24vdc) Mini lathe

it came with an adjustable power supply 12-24vdc, some basic tools, an affixed drill chuck, a crudely adjustable tailstock , and a 45mm tool rest, some very inexpensively designed and made turning tools (throw these tools out unless you are going to be turning objects the magnitude of strength of a toothpick, they are poorly made turning tools- but really, what do you want though for $38???? )

after turning a sample piece in softwood (pine), i decided the lathe was in desperate need of modification.

the power was sufficient, but the spindle speed at 24vdc was way too fast for my taste

i ran through the available voltage selections, taking cuts with each.

running it on the 12vdc setting dropped the available torque, but brought the spindle speeds to workable levels

the lack of a finely adjustable tailstock meant that work needed to be held in the chuck or held by screw mandrel -

a spur drive center worked but , the lack of a tailstock screw adjustment made pressure turning sketchy at best

i decided to remove the existing tailstock and install a purchased adjustable tailstock assembly

i screwed up the vertical clamp on the purchased tailstock by knocking off too much material, trying to get the center height right.

shims were unacceptable.

i decided to reproduce the vertical clamp

some scrap 6061, was used

in the BP mill i roughed out the basic size

left: original tailstock clamp , center: clamp billet , right: purchased adjustable tailstock

i got the basic form and used the original tailstock platform to drill a dimple to get the correct center height.

i transferred the billet to the Unimat for drilling the pilot hole

i drilled the center to 5/8", reamed to 16mm to accept the tailstock capsule , cross drilled to 4mm

i returned the clamp to the Unimat for slitting with a precarious set up

after slitting, i drilled one half of the clamp to 5.5mm, tapped the other side to 5mm, and installed a clamp bolt

i drilled and tapped the base of the tailstock to accept the retrofit adjustable tailstock, swapped out wing nuts for round head hex screws

i installed the adjustable tailstock quill into the clamp block and set the projection