-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Saving a Logan 825

- Thread starter bhusted

- Start date

- Joined

- Oct 18, 2016

- Messages

- 2,872

You wouldn't happen to have any creative solutions for powering this thing, would you?

More pics please. Lets have a look at your headstock from the back side as well as from above.

Although, judging from the pics you've already posted, you have a bit of work to do before you need a motor...

Okay. I'll get some more pictures today. The head-stock drive is comprised of a double groove v-belt approximately 3" OD. It's my understanding that the belts are intended to go down through the bed and into the cabinet where the jackshaft and motor would live. There is no opening in the back of the head-stock for belts to pass through.

I did some browsing on eBay last night and found several DC motors for about $100 that could potentially be mounted under the bed. Using a 2" OD pulley on the motor would bring it down to a max speed of 1100rpm at 90v DC. With a double pulley and almost 180 deg of belt wrap, I should think that this arrangement would be suitable provided that the motor develops sufficient torque.

I know that I'm a long way off from getting this lathe up and running, but I want to have a plan for how to power it before I put too much time into repairs. If I can't run it, selling as a whole will be difficult and I may need to resort to selling it for parts.

I did some browsing on eBay last night and found several DC motors for about $100 that could potentially be mounted under the bed. Using a 2" OD pulley on the motor would bring it down to a max speed of 1100rpm at 90v DC. With a double pulley and almost 180 deg of belt wrap, I should think that this arrangement would be suitable provided that the motor develops sufficient torque.

I know that I'm a long way off from getting this lathe up and running, but I want to have a plan for how to power it before I put too much time into repairs. If I can't run it, selling as a whole will be difficult and I may need to resort to selling it for parts.

- Joined

- Apr 30, 2015

- Messages

- 11,288

I would say you might want another stage of speed reduction considering the headstock you have. Most DC treadmill motors will be somewhere in the range of 2500 rpm or less (probably less) but being able to slow your spindle down to around 60 rpm (with backgears)

can be very useful for threading and some types of interrupted cutting.

The KB brand of dc speed controls are excellent and can sometimes be found on Ebay for less than 50$

Often times the treadmill controllers are too clumsy to use (speed adjustment with up/down buttons, slow ramp start up, etc.)

DC motors have good torque at low rpm

-Mark

can be very useful for threading and some types of interrupted cutting.

The KB brand of dc speed controls are excellent and can sometimes be found on Ebay for less than 50$

Often times the treadmill controllers are too clumsy to use (speed adjustment with up/down buttons, slow ramp start up, etc.)

DC motors have good torque at low rpm

-Mark

Last edited:

- Joined

- Dec 25, 2011

- Messages

- 10,511

If I remember correctly, you have to level up to Gold Member status before you have access to downloads.

Actually, any Donor level from Silver ($10.00 per year) on up has access to Downloads. The other common privilege that requires Gold level ($25.00 per year) is the ability to list items for sale.

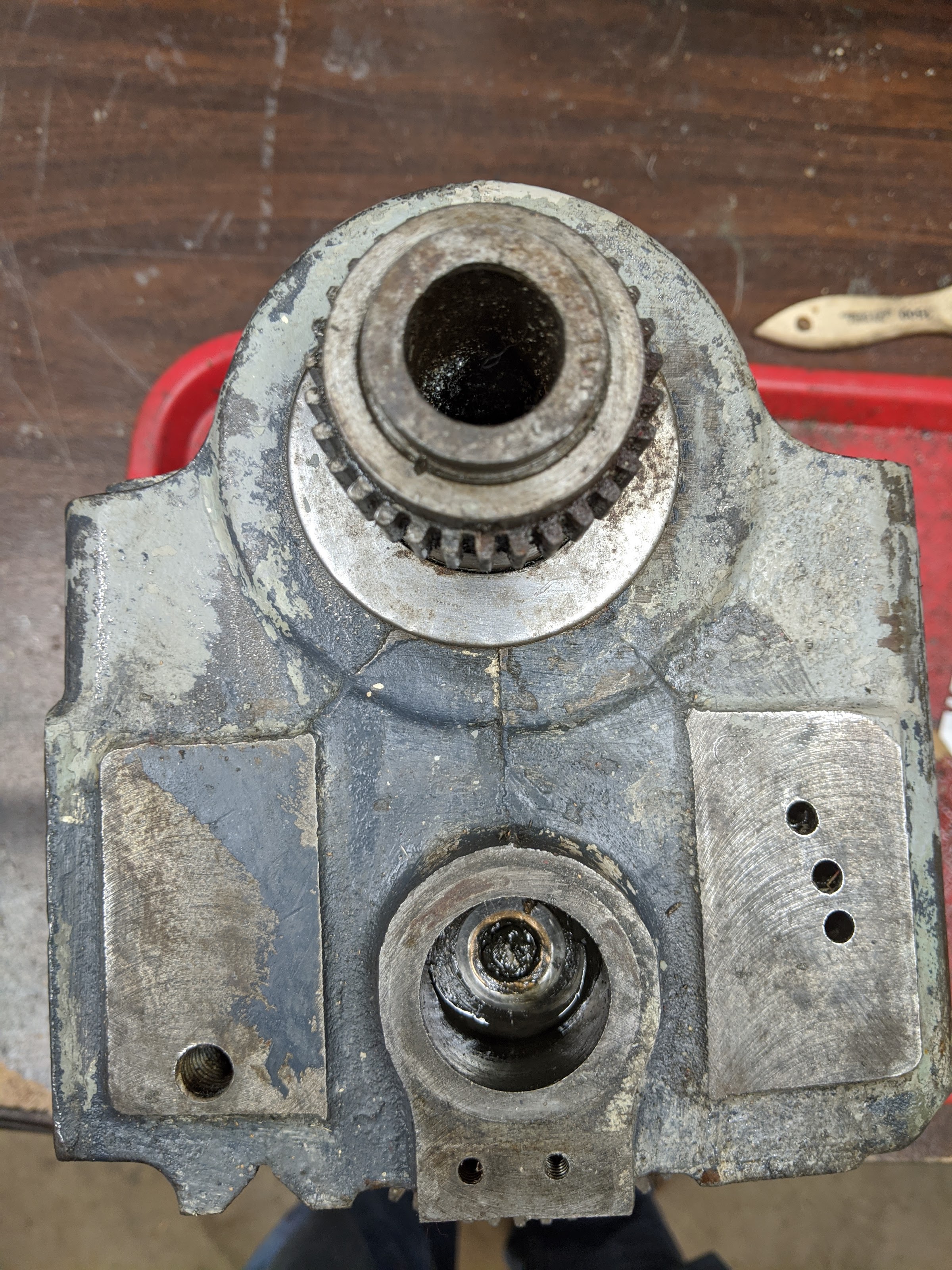

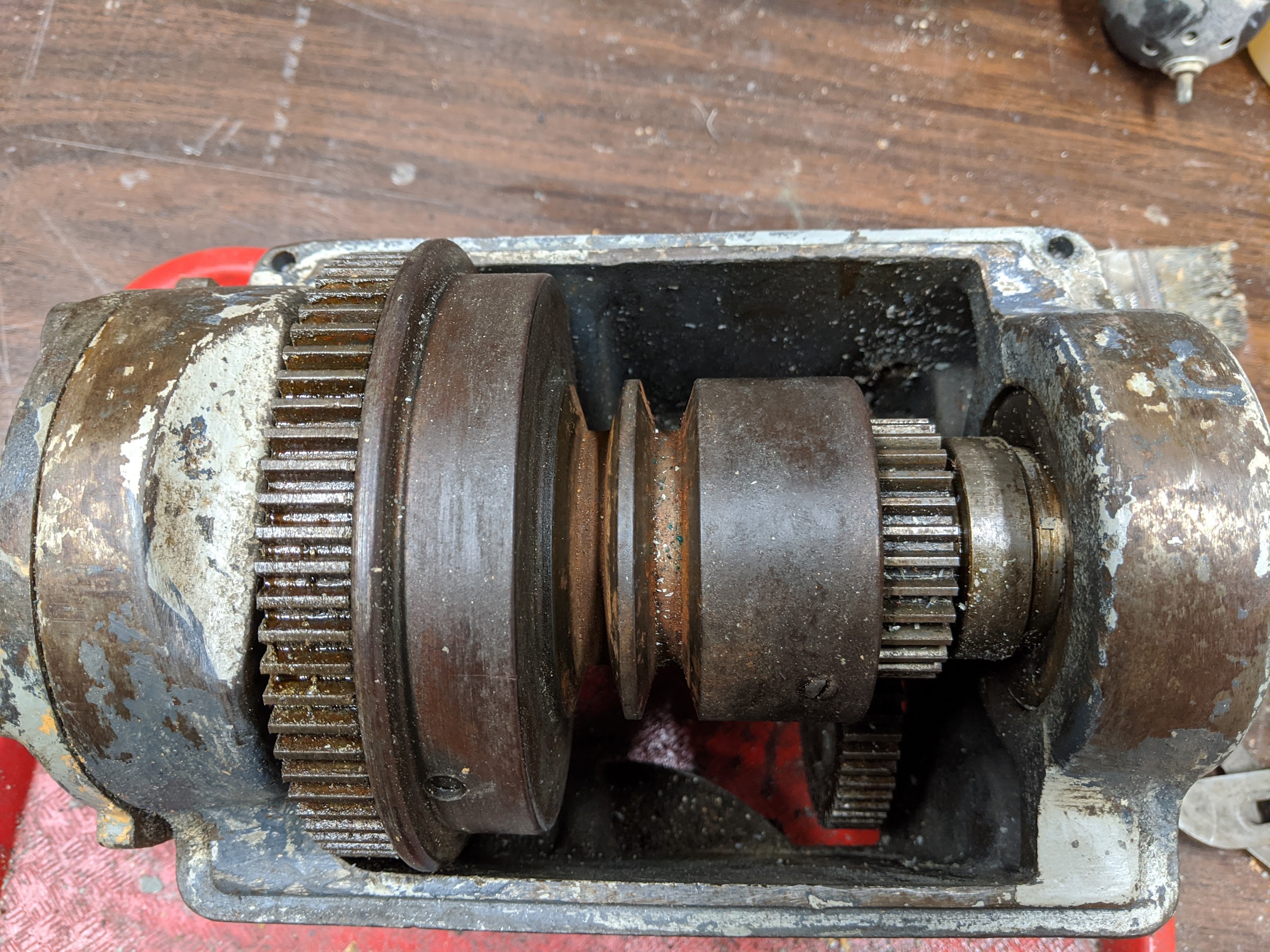

Here are some additional pictures of the head-stock. I spent a little time scraping off a few layers of paint and grease and it already looks less daunting. Unfortunately, I discovered one missing tooth on the large back gear. The spindle threads are not in great shape, but are serviceable. The take-up nut on the back of the spindle looks like someone has had at it with a punch.

- Joined

- Oct 18, 2016

- Messages

- 2,872

As long as it's going to be steam powered, you might as well drop a belt down from an overhead line shaft while you're at it.

Any other ideas for powering this thing other than using my model steam engine? This is the type of DC motor that I've been thinking of.

90v DC motor 1750rpm

My plan would be to mount it from the bed underneath the head-stock. I don't have any really good dimensions to go off of for if it would fit or not. The mounting flange may have to get modified and the electrical box is probably in the way. The fan would also probably be in a prime location to pickup chips.

Another thought I had was to find a head-stock from a 820 model to mount the motor off of the back side, using the pulley arrangement on my current spindle.

90v DC motor 1750rpm

My plan would be to mount it from the bed underneath the head-stock. I don't have any really good dimensions to go off of for if it would fit or not. The mounting flange may have to get modified and the electrical box is probably in the way. The fan would also probably be in a prime location to pickup chips.

Another thought I had was to find a head-stock from a 820 model to mount the motor off of the back side, using the pulley arrangement on my current spindle.

May be able to mount a motor behind the HS if you mod the HS casting.

Here's a youtube 825 restore: https://www.youtube.com/channel/UCVYxpZ1B3c41ZysowqKMXsg/search?query=logan

Here's a youtube 825 restore: https://www.youtube.com/channel/UCVYxpZ1B3c41ZysowqKMXsg/search?query=logan

Last edited: