That machinetoolcollectionitius disease struck again. I picked up a 16" x 60" SB today.

Came with a 12" 4 jaw, complete 5c collet set, with a nice tray, that someone set up to mount at the tail stock, or head stock. A well abused 8" 3 jaw (yes, thats a crack above the 5 &6). a spare 8" backing plate, the wrenches for the saddle and tail stock locks, and a 4 way tool post. And most of a steady rest(missing the fingers, but the knobs and all are all there).

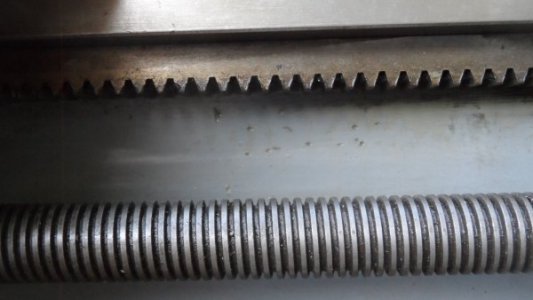

The ways have a good bit of wear. The travel knob for the saddle needs a new bushing, or something, but is quite usable the way it is. Otherwise, all the gears look good. He never did any threading, so the threading dial was never engaged as long as he had it.

Came with a 12" 4 jaw, complete 5c collet set, with a nice tray, that someone set up to mount at the tail stock, or head stock. A well abused 8" 3 jaw (yes, thats a crack above the 5 &6). a spare 8" backing plate, the wrenches for the saddle and tail stock locks, and a 4 way tool post. And most of a steady rest(missing the fingers, but the knobs and all are all there).

The ways have a good bit of wear. The travel knob for the saddle needs a new bushing, or something, but is quite usable the way it is. Otherwise, all the gears look good. He never did any threading, so the threading dial was never engaged as long as he had it.