Confidence level is through the roof now. I've got the tailstock finished. Woo hoo!

Less than 0.0002" along a 9 or 10" test bar in both the vertical and horizontal planes. Since my individual scrapes themselves are about 0.00025" deep this really amazes the engineering nerd in me. Behold the glory:

The horizontal plane is also well under one indicator division over the full length of the test bar.

The stack of potential errors is astonishing:

1. Flat inner bed way

2. Side one of the inner inverted vee way

3. Side two of the inner inverted vee way

4. Flat bearing surface on the bottom of the tailstock base

5. Side one of the vee on the bottom of the tailstock base

6. Side two of the vee on the bottom of the tailstock base

7. Front half of the top of the tailstock base (in front of the bump)

8. Back half of the top of the tailstock base (behind the bump)

9. Bottom of the top half of the tailstock.

10. Bored hole for the quill (I've not touched this)

11. Morse taper hole in the quill (freshly reamed to remove any burrs)

12. Morse taper of the test bar (not touched nor tested)

13. Ground cylinder of the test bar (I've not touched nor indicated this, though I should)

Before anyone asks, NO I AM NOT GOING TO EVEN LOOK AT IT WITH MY TENTHS INDICATOR. (Laugh) Seriously, two tenths at the end of a foot long bar is so crazy precise that even breathing on the thing (literally, I think!) will affect the results.

Anyway, I'm confident enough to start work on the headstock tomorrow. It will be a little more nerve wracking because I have to make any alignment adjustments on relatively small way surfaces instead of big flat areas like the top of the tailstock base. It will also be a little more nerve wracking because it's the freaking spindle, the heart of the lathe!

A few interesting things from today's work:

When I first indicated in the vertical plane after flattening the bottom of the upper half, I almost freaked out. The end of the bar at the headstock end was 0.0065" lower than the other end. I thought I was going to be scraping for days (at roughly four passes per thou, I thought at first I'd need 24 passes).

Then I realized it's over a foot from the back end of the tailstock. Tiny little changes back there have a big effect at the end of the bar. Whew.

In the end it only took me a couple hours at most to get it to the point you see in the video.

Since the upper half of the tailstock has a channel rather than a bump, I could just mark it up on the surface plate. After getting it roughly flat (maybe 5-10 PPI) I inked up the bottom half and checked the fit. I was extremely gratified to see almost identical markup using to the bottom half as I did with the plate (proving I did a decent job scraping in the bottom half despite the bump). Cool.

So I spent the next several passes fitting it to the bottom half. Once I had it bearing pretty well everywhere (maybe 15-20 PPI) I blued it up once more on the plate.

And almost had a heart attack. It was bearing on only a few points! What on earth had I done?

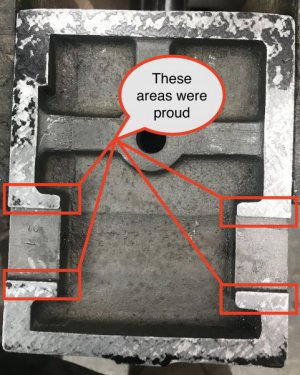

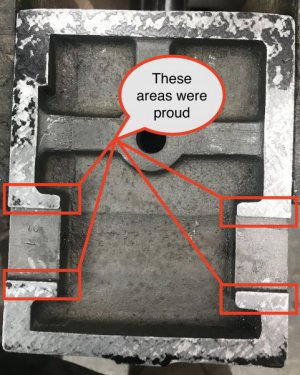

Eventually (walks, cursing, coffee, etc.) I realized that the clearance grooves I'd filed into the bottom half had come back to haunt me. Since there was no bearing where I'd filed the grooves, and I'd gone through a dozen or so scraping passes, those areas on the top half hadn't been scraped at all and were now proud by a few thou. I forgot to take a picture of the original mark up, but here it is in the middle of one of the corrective passes:

Anyway, today was a good day.

Next up is the headstock. Hopefully the results will be equally good.