I got another good hour of scraping in yesterday and was pretty spot on with my guess of 1 hour to correct the damage done by the stone.

I now have a nice and flat surface with decent bearing contact. I have a few hollows, but I expect them to fill in as I start high pointing. I am getting about 20-30 points per inch all over with 5 points per inch in the bare sections. All of my contact points are tiny so I only think I have 5% bearing or so. Doesn't quite look like the pictures I see of finished scaping yet.

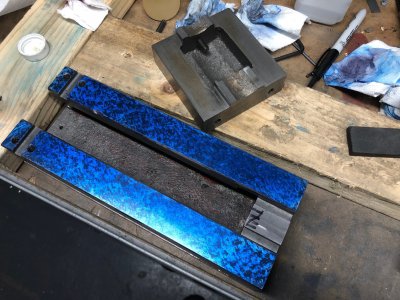

In the image below I've marked all my high points with sharpie. This both makes it possible to share a picture of the work here as well as helps me when I go to actually scrape this in.

You can see some bare spots in the top left corner, along the very right edge, and a higher distribution at the edges of the bed rails compared to the middle.

What I learned on day 3:

1) A lot of damage can be done to a surface very quickly, and it is very slow to repair

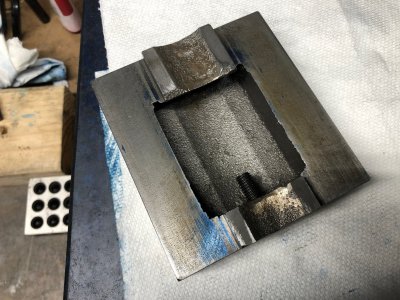

2) A very light rubbing of blue followed by a dry rubbing on the surface plate creates a bunch of blue circles with a burnished (almost black looking) dot in the middle. In the later stages of scraping this makes it easier to see your high points

3) The wide radius of the stock Sandvik blade wasn't too bad to rough with, but I feel I am having accuracy issues with aiming for high points. I have started to develop a tighter radius on the blade but that is a lot of work when shaping completely by hand.

4) I can see my work better with a single overhead light rather than all the lights on in the basement. Makes it easier to get a contrast between the surface and the high points.

I think I will high point for an hour and see where I get to. Would like to see a slightly more even distribution before I call it finished.

Then I get to go back and work on getting the bottom parallel to the bed.