- Joined

- Mar 5, 2012

- Messages

- 161

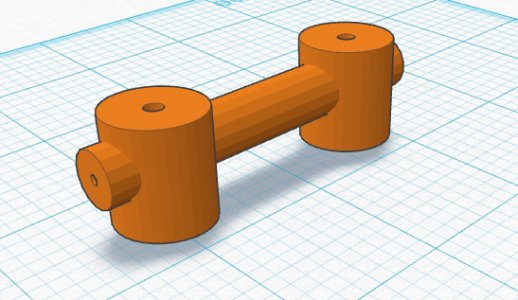

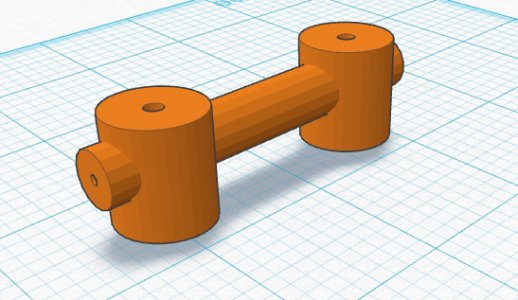

As the title says, I am seeking a machine shop in SE Michigan willing to make 100 or so of the items shown below. Likely material is 304 stainless. The horizontal tube is approximately 2.5 inches long, 5/16 thick with an interior thread (end to end, but larger than shown). Each of the smaller upright parts are approximately 5/8 thick and 1 inch tall. They are threaded from the bottom. However the hole in these upright parts does not extend all the way through.

I thought I could make these, but got only mediocre results in aluminum. I quickly realized that I may never be even a decent machinist. These are part of a much larger project. I don't want to get sidetracked while learning the art and craft of lathe work. It's really much more time consuming and challenging than I ever imagined.

Would appreciate any thoughts. Heck, maybe I don't need a machine shop... someone on this board likely has the skill and time that I don't!

Thanks in advance for all advice.

Jim

I thought I could make these, but got only mediocre results in aluminum. I quickly realized that I may never be even a decent machinist. These are part of a much larger project. I don't want to get sidetracked while learning the art and craft of lathe work. It's really much more time consuming and challenging than I ever imagined.

Would appreciate any thoughts. Heck, maybe I don't need a machine shop... someone on this board likely has the skill and time that I don't!

Thanks in advance for all advice.

Jim