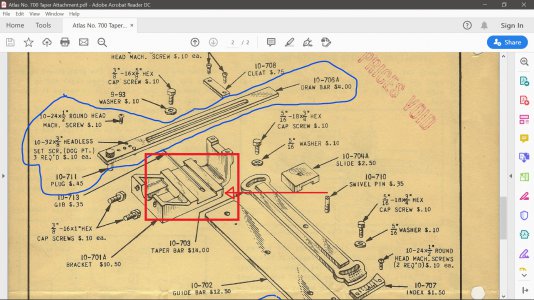

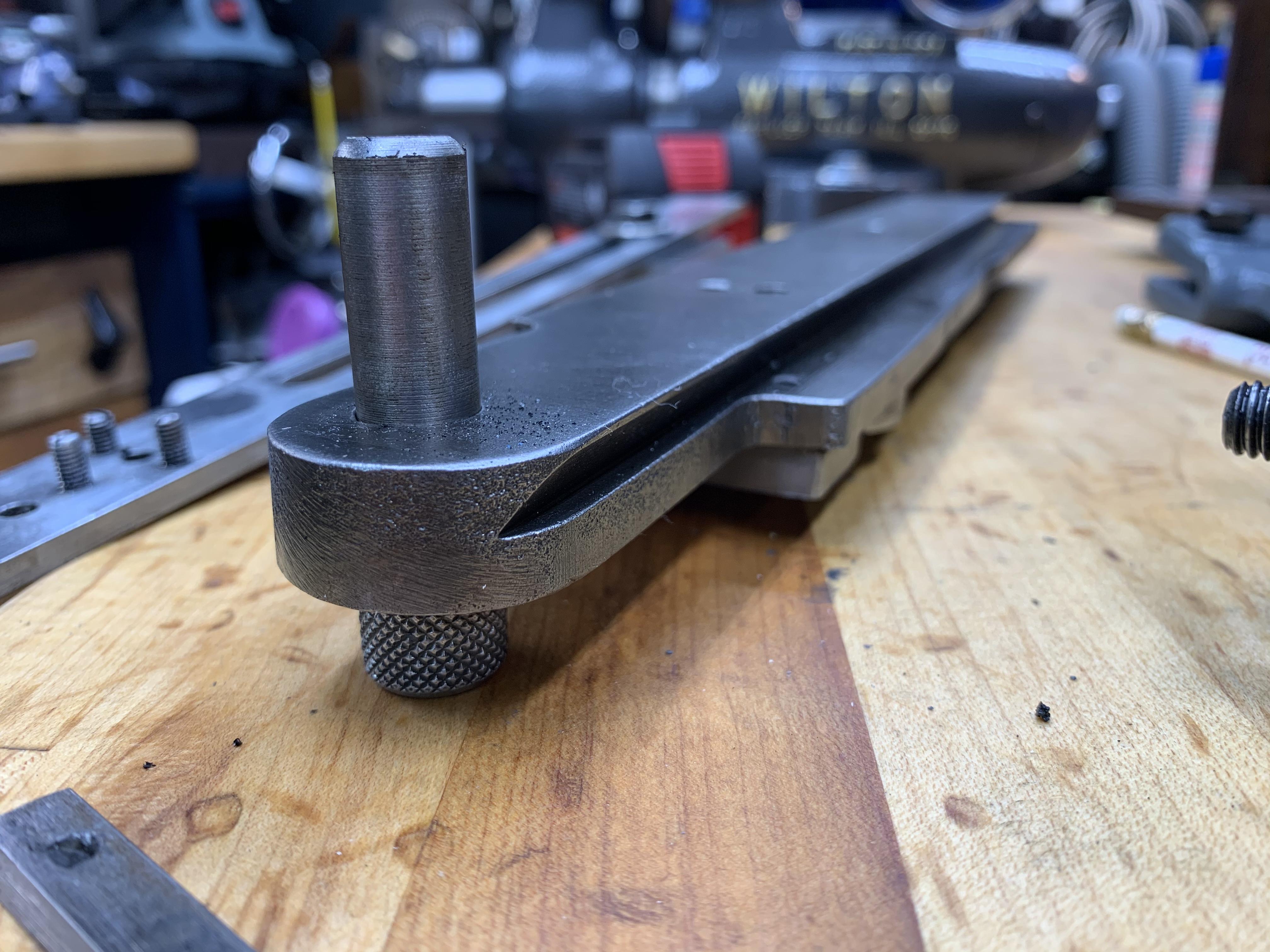

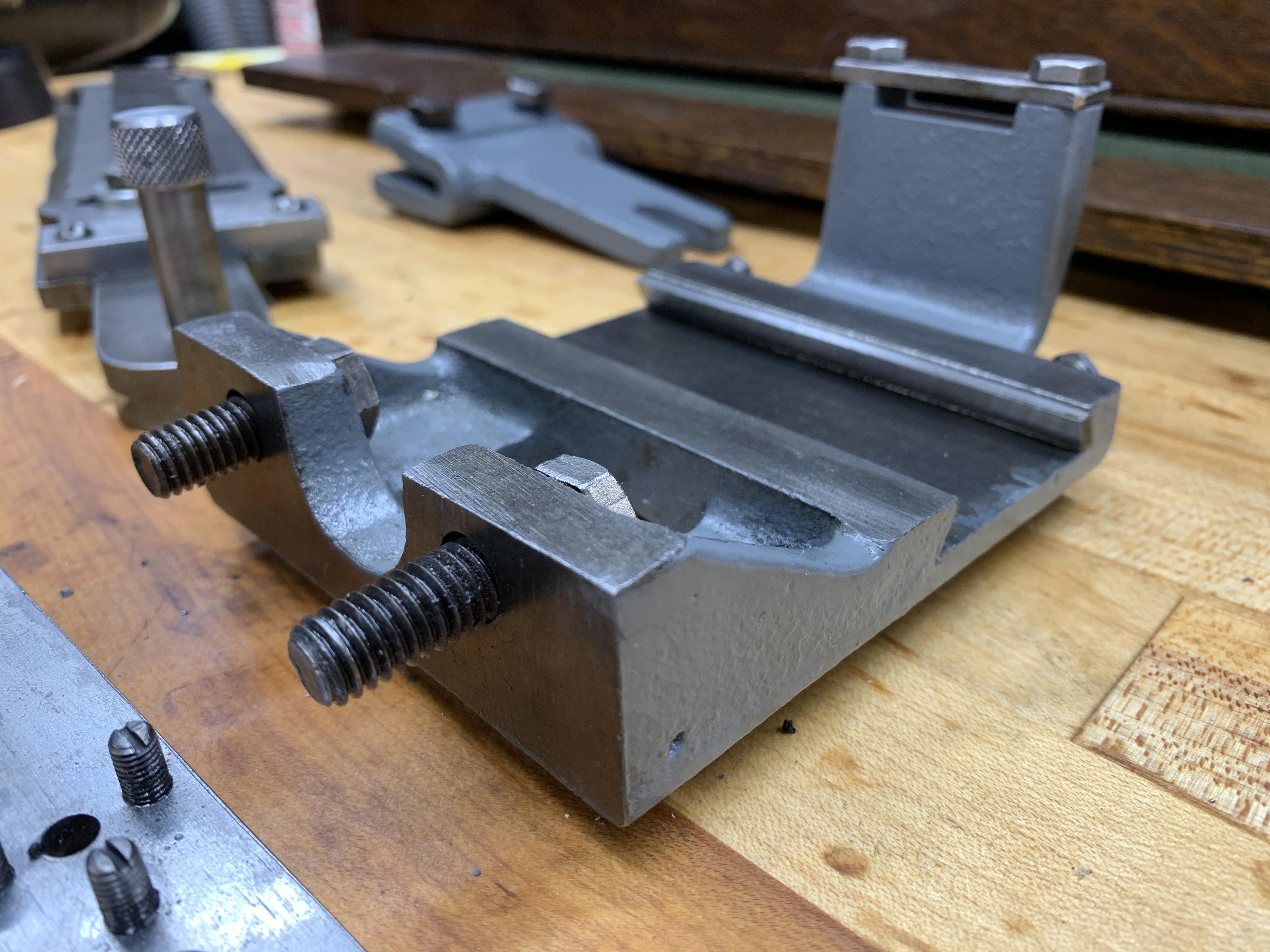

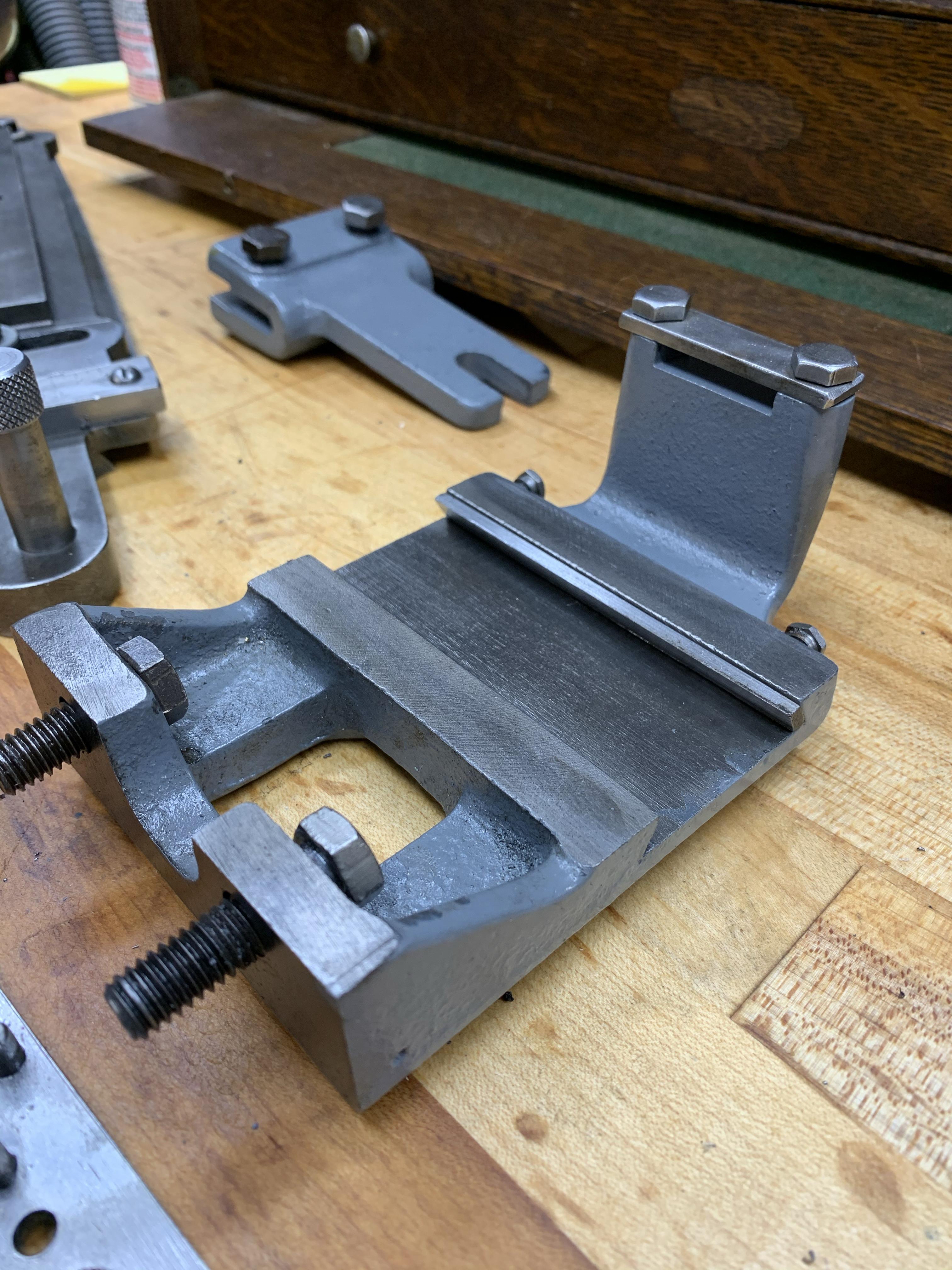

OK. The most recent batch of photos answered my questions. The drawing in the manual copy of the right end of the guide bar is wrong as your first photo in this series shows that the dovetail on the bottom of the (inverted in the photo) guide bar should be clearly visible as it extends out all of the way through the radiused right end. And the drawing of the tailstock side of the Bracket is wrong. As drawn, the near (to the operator) line representing the front edge of the right end of the dovetail is drawn too close to vertical. It should be laid over more to the right. But now that I know that the dovetail should be visible on the front of the handle on the right end of the guide bar, I probably wouldn't have questioned the bracket drawing.

Also, there are two other errors in the text part of the instructions for installation and use of the 700 Taper Attachment. As with the 760 and 6822, Step 1 for installing is to remove the chip guard and attachment screw from the rear of the cross slide. Step 2 is to remove the cross feed brass nut and its attachment screw. Then proceed with the rest of the installation instructions.

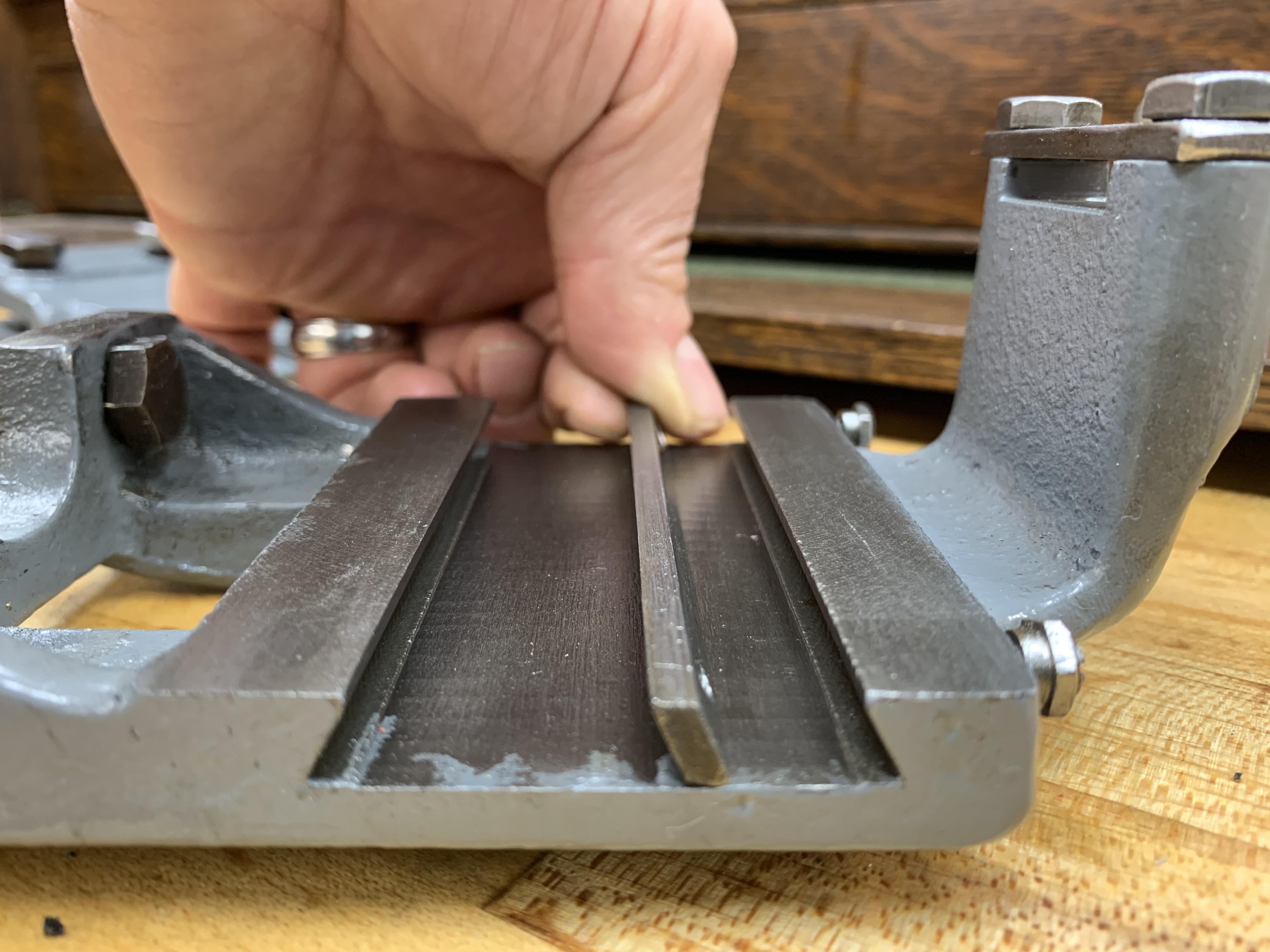

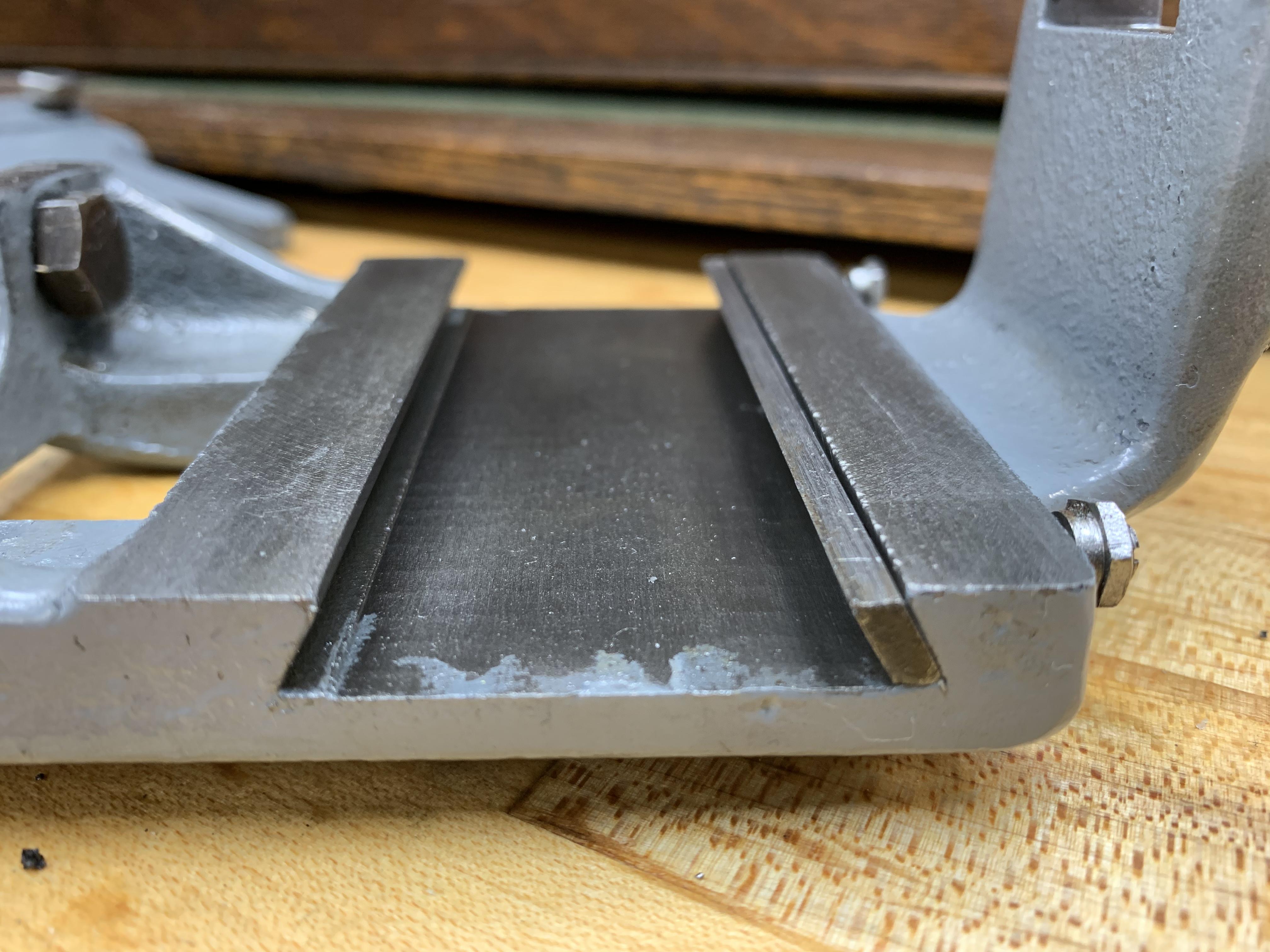

The 10-24 x 1/2" round head mach. screw shown above the left end of the draw bar goes into the hole formerly occupied by the chip guard. Tighten it after installing the pin through the draw bar and into the hole formerly occupied by the cross feed nut and adjusting the three 10-32 x 3/8" set screws. After tightening the screw but with the screw for the 10-704A Slide loose, confirm that the cross slide and draw bar move freely across the carriage. This is your coarse adjustment of where cutting is going to take place. After tightening the bolt through the draw bar into the 10-704A Slide, all further adjustment will be done with the compound feed. The compound slide should be set to 0 deg. and if you are using either a QCTP or a 4-way turret, they should be square with the lathe axis or with the piece of solid round that you usually start with.

One further tip - before starting the installation, check and if necessary adjust the carriage gib screws.