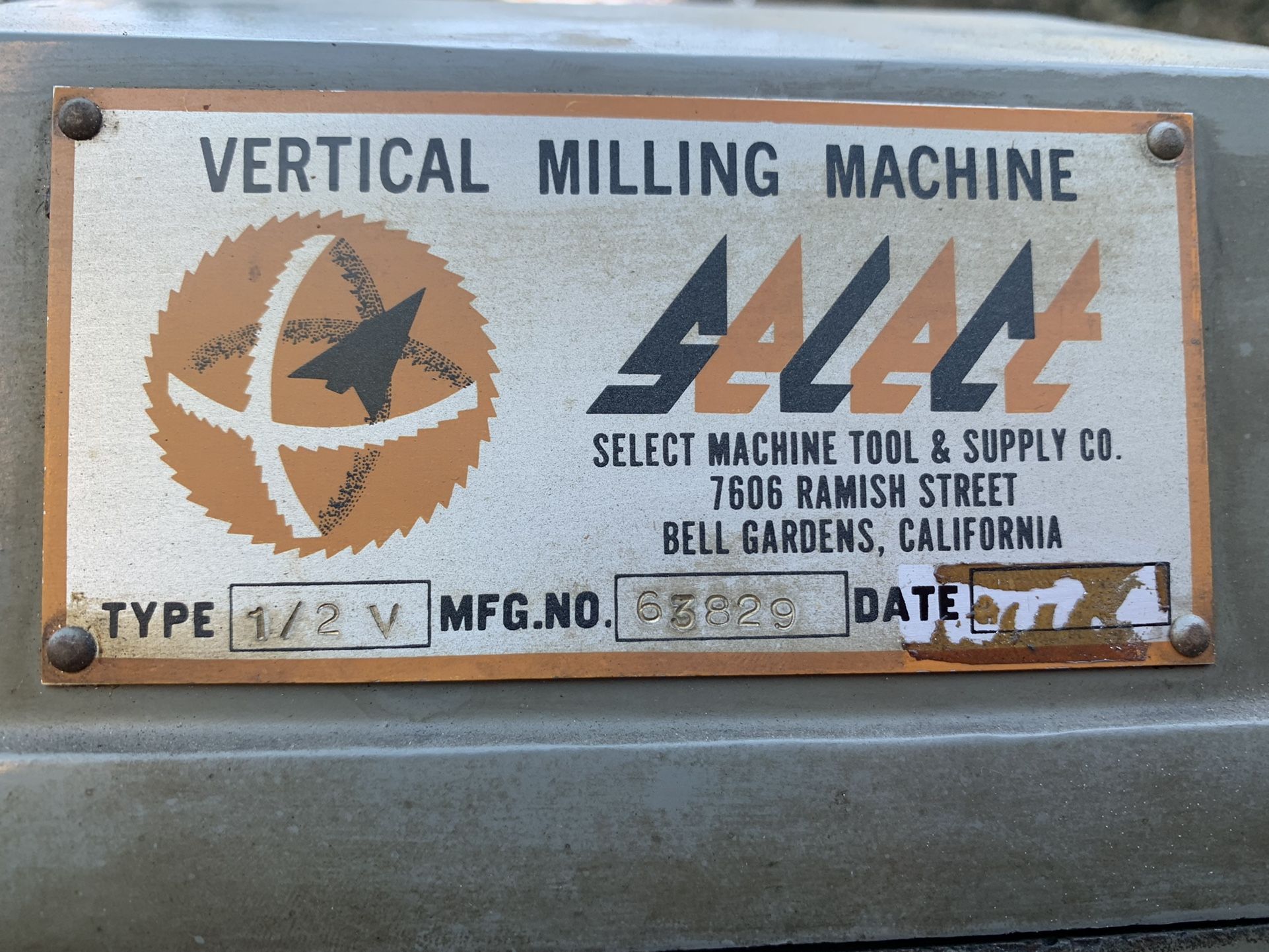

I've been looking for a "deal" on a manual mill for a few years and finally got lucky Friday on OfferUp when I found this one owner Select 1/2V in excellent condition for $1300.

I picked it up from a friend of it's owner, who sold it for him and had a skid steer with forks to load it. It was purchased new and put in the corner of a garage where it was rarely used. It seems to be super tight and shows zero wear on anything. The belts are dry rotted and cracking but it runs nice and the spindle is quiet. The quill is a little gummy feeling so I'll lube it up with Marvel Mystery Oil until it loosens up.

I found this forum looking for information about it. In one of the other Select threads someone posted a 1979 machine with a higher serial number than mine so I'm guessing it's older than that. The year was never stamped on this machine's ID plate. It looks like there was a sticker there or something.

I picked it up from a friend of it's owner, who sold it for him and had a skid steer with forks to load it. It was purchased new and put in the corner of a garage where it was rarely used. It seems to be super tight and shows zero wear on anything. The belts are dry rotted and cracking but it runs nice and the spindle is quiet. The quill is a little gummy feeling so I'll lube it up with Marvel Mystery Oil until it loosens up.

I found this forum looking for information about it. In one of the other Select threads someone posted a 1979 machine with a higher serial number than mine so I'm guessing it's older than that. The year was never stamped on this machine's ID plate. It looks like there was a sticker there or something.