- Joined

- Feb 8, 2014

- Messages

- 11,144

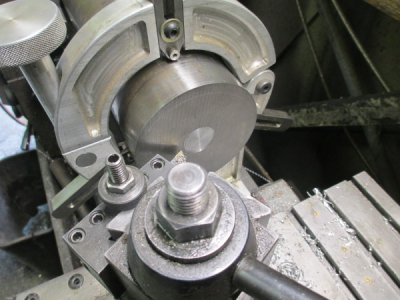

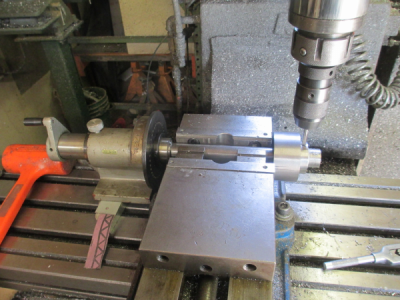

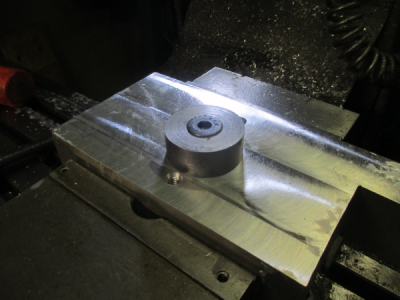

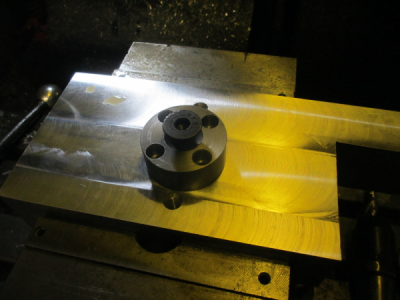

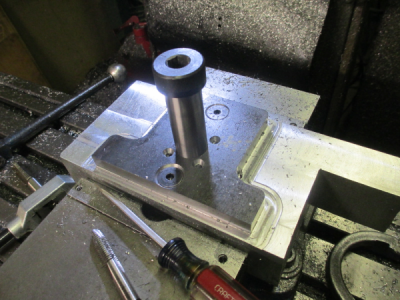

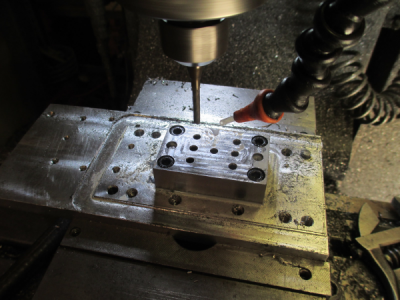

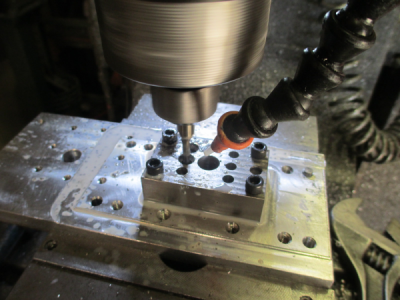

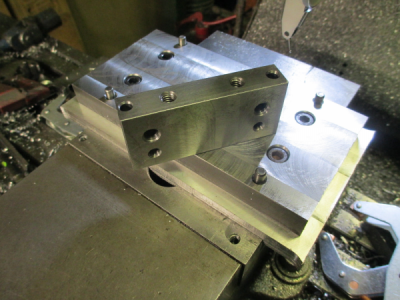

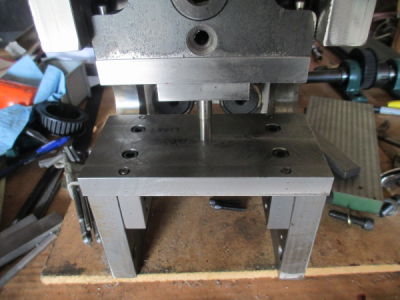

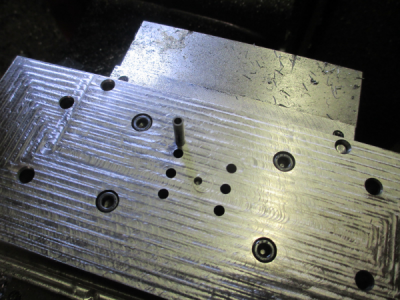

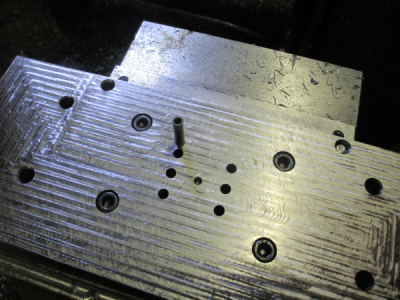

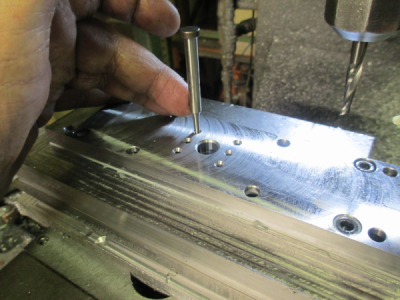

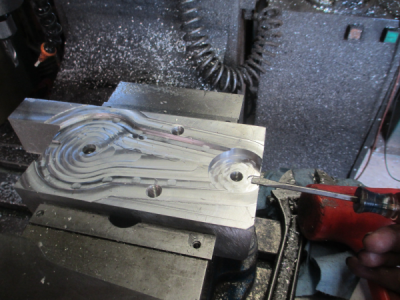

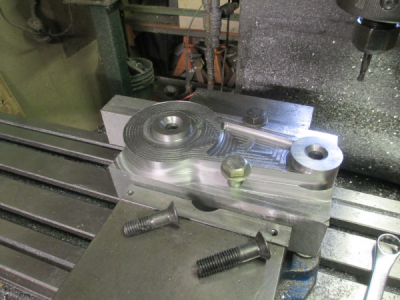

OK in the previous post one side of the connecting rod was finished, so now is time to do the other side. So first mill a con rod shaped pocket into the aluminum. 0.125 deep and a loose press fit. This locates the part exactly back relative to 0,0 without having to dial anything in after it's turned over. The screwdriver pockets are so it's possible to get the part out of the aluminum block, you need to pry it out.

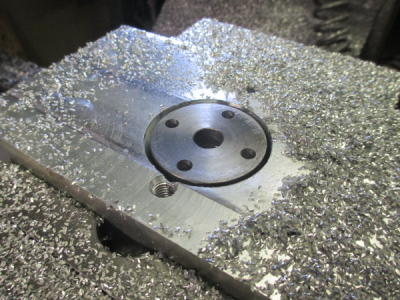

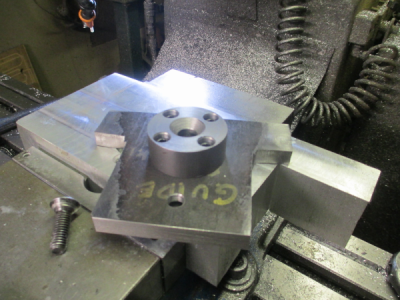

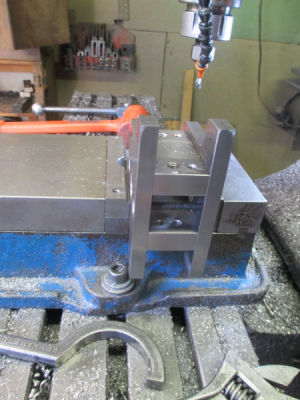

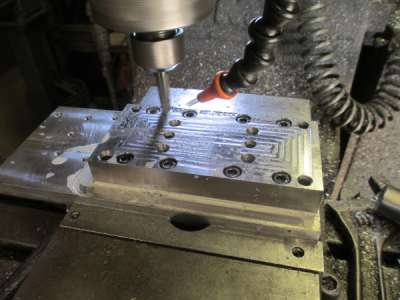

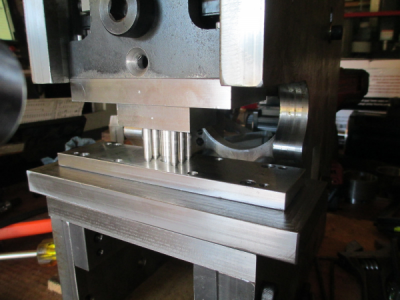

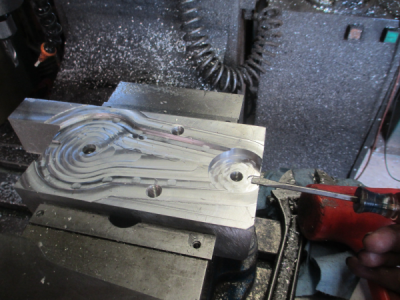

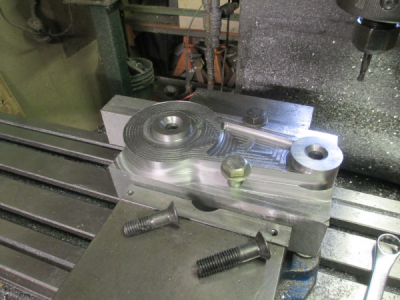

The same operations were performed on this side as the first side. I left the ''island'' on the crank end because I didn't have enough meat in there to counter bore for a screw. So I used flat head screws on this side for tool clearance.

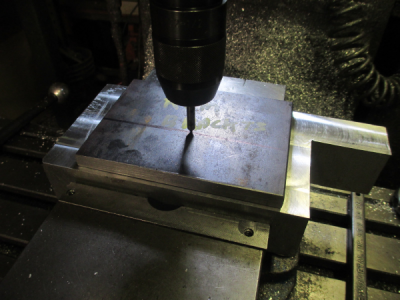

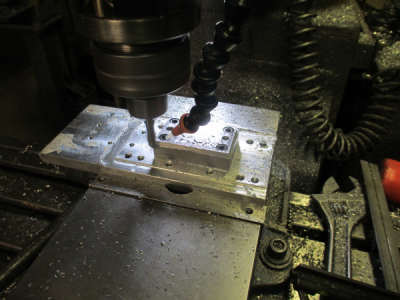

Also you now see why the side screw holes were there. All they have to do is hold the part down, the pocket holds it in location. The next step is to pocket and bore the bearing and pin holes.

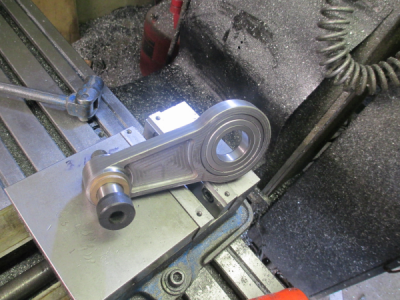

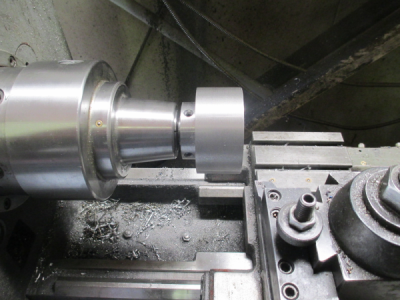

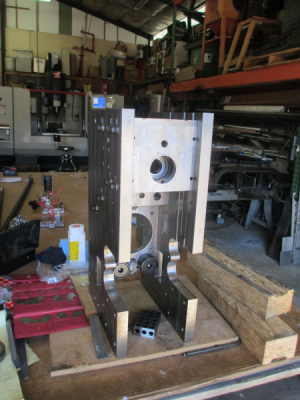

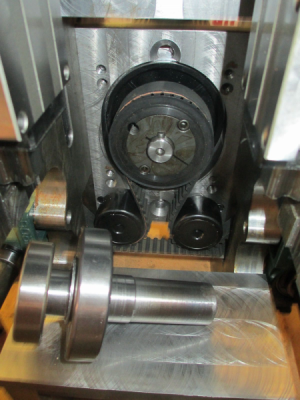

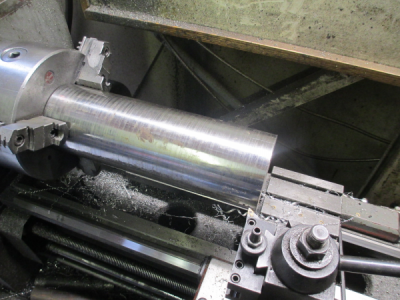

While the con rod was running, I was setting up to fab up the feed rollers in the lathe.

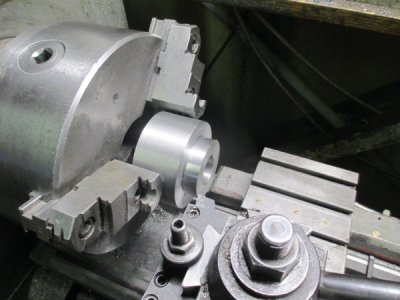

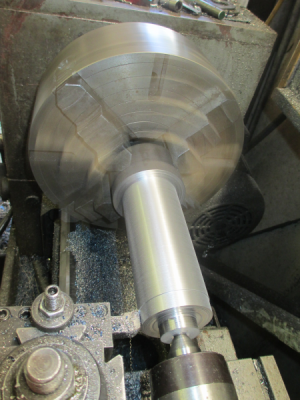

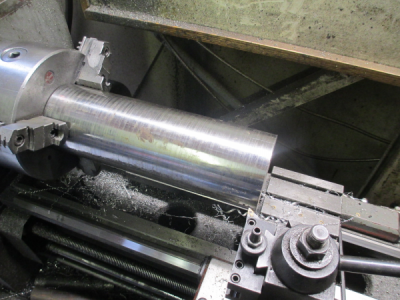

12 x 4 inch dia 8620. This was another bit of a screw up on my part, originally I designed the rollers to be 3.800 dia, and ordered the material. After a design review I decided to make the feed rollers 2.75 diameter so I'll be making a lot of chips to get this down to size.

Does this look like too much stick out?

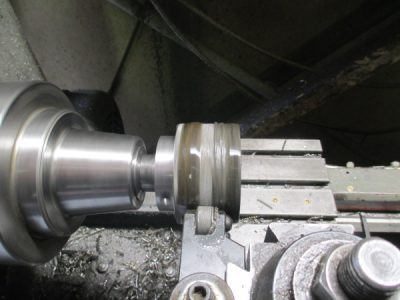

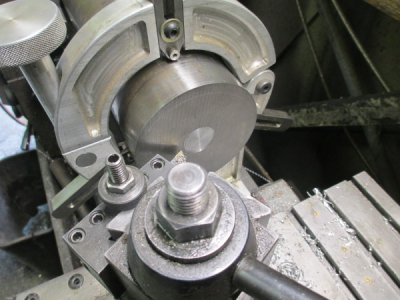

Yeah, I guess it is. Note: The chuck jaws are at the absolute limit of extension where I will run them. So support it in the steady rest to face and center drill. For center drilling I normally face a small area, in this case about 1 inch dia. Then center drill and then finish the face after the center is in place.

Note: The chuck jaws are at the absolute limit of extension where I will run them. So support it in the steady rest to face and center drill. For center drilling I normally face a small area, in this case about 1 inch dia. Then center drill and then finish the face after the center is in place.

The same operations were performed on this side as the first side. I left the ''island'' on the crank end because I didn't have enough meat in there to counter bore for a screw. So I used flat head screws on this side for tool clearance.

Also you now see why the side screw holes were there. All they have to do is hold the part down, the pocket holds it in location. The next step is to pocket and bore the bearing and pin holes.

While the con rod was running, I was setting up to fab up the feed rollers in the lathe.

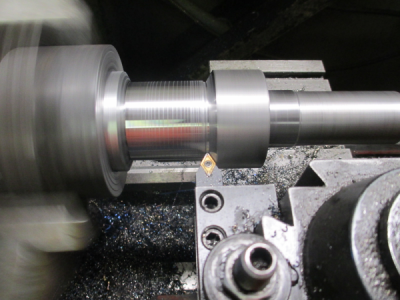

12 x 4 inch dia 8620. This was another bit of a screw up on my part, originally I designed the rollers to be 3.800 dia, and ordered the material. After a design review I decided to make the feed rollers 2.75 diameter so I'll be making a lot of chips to get this down to size.

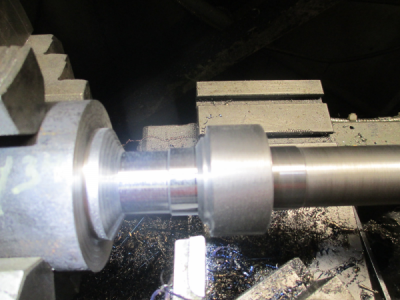

Does this look like too much stick out?

Yeah, I guess it is.

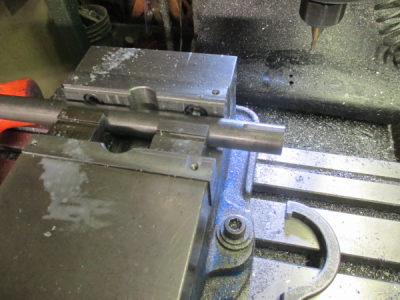

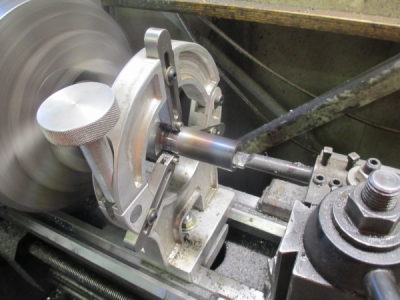

Note: The chuck jaws are at the absolute limit of extension where I will run them. So support it in the steady rest to face and center drill. For center drilling I normally face a small area, in this case about 1 inch dia. Then center drill and then finish the face after the center is in place.

Note: The chuck jaws are at the absolute limit of extension where I will run them. So support it in the steady rest to face and center drill. For center drilling I normally face a small area, in this case about 1 inch dia. Then center drill and then finish the face after the center is in place.