- Joined

- Jan 2, 2019

- Messages

- 6,489

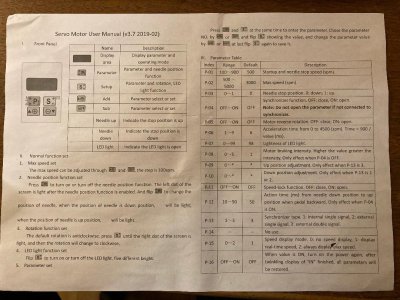

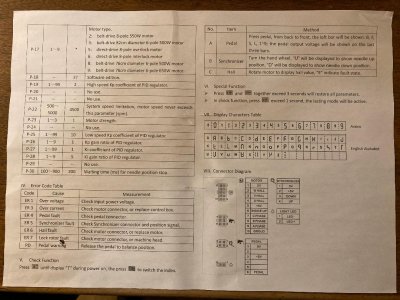

I bought one of these cheap sewing machine servo motors and it seemed fine for a short time then it started running rough at high speed.

So I tore it apart expecting to find a bad bearing but the bearings seem tight and smooth. Now I'm wondering if it might be a problem with the cheap controller. I'm looking for a manual that might specify some kind of tuning operation or anything else that could help. This is the manufacturer but they don't seem to have any more info than the eBay seller.

www.vevor.com

www.vevor.com

I'm pretty clueless on servo operation so anyone who might have insight into this would be appreciated.

John

So I tore it apart expecting to find a bad bearing but the bearings seem tight and smooth. Now I'm wondering if it might be a problem with the cheap controller. I'm looking for a manual that might specify some kind of tuning operation or anything else that could help. This is the manufacturer but they don't seem to have any more info than the eBay seller.

TOUGH TOOLS, HALF PRICE | VEVOR Tools | VEVOR Store

VEVOR store offers a full range of equipment & tools, kitchen supplies, home & garden service, etc. Shop our premium products at affordable prices.

I'm pretty clueless on servo operation so anyone who might have insight into this would be appreciated.

John

Can I guess ?

Can I guess ?  BTW , we never read manuals .

BTW , we never read manuals .