4

4GSR

Forum Guest

Register Today

Pacer,

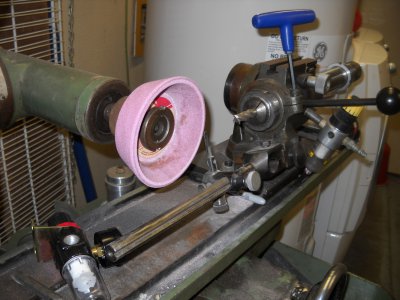

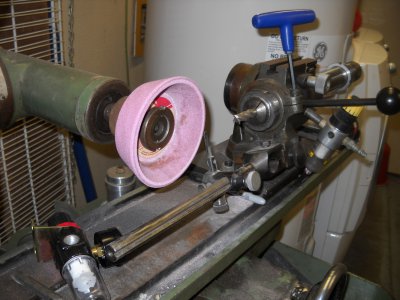

Tony is right, you almost have to be trained to grind endmills properly and get all of the relief angles set and cut properly on a endmill. I've done my share of endmill sharpening years back and come back to it and do it again 10 years later, its almost relearning it all over. Here's a couple of pictures of my setup on a junkie Tiawaneese tool and cutter grinder that Big Joe sold years ago. I kept this from the family shop dad had many years ago.

If you are still serious about endmill grinding I may make up step by step instructions on endmill grinding. Just for OD sharpening of end mills. I haven't perfected a good method for grinding the ends. Still working on that.

Tony is right, you almost have to be trained to grind endmills properly and get all of the relief angles set and cut properly on a endmill. I've done my share of endmill sharpening years back and come back to it and do it again 10 years later, its almost relearning it all over. Here's a couple of pictures of my setup on a junkie Tiawaneese tool and cutter grinder that Big Joe sold years ago. I kept this from the family shop dad had many years ago.

If you are still serious about endmill grinding I may make up step by step instructions on endmill grinding. Just for OD sharpening of end mills. I haven't perfected a good method for grinding the ends. Still working on that.