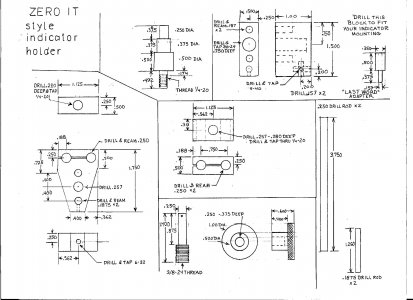

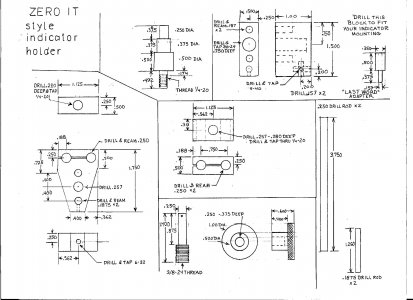

Hi Mark, Great looking tools there. I really like that zero-it style indicator holder. Do you have prints for that? Or more specifacally, How is the screw held to the bearing in the holder? Also what diameter and pitch did you make it? I have wanted one of those for a long time.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

shop made tooling

- Thread starter Mark_f

- Start date

- Joined

- Nov 24, 2013

- Messages

- 1,791

There should be prints in the prints section here on the site.

- Joined

- Oct 20, 2014

- Messages

- 495

First off, you make beautiful tools. It shows attention to detail, plus your skill in running a machine.

As for the people who try to run you down, don't sweat 'em. They're probably jealous that you make functional works of art, and all they can make is chips and chatter-marked scrap.

Pardon my crudity here for a moment....

Nobody pops out of their mother's hoo-ha a master machinist. Or a master of anything, except crying, suckling, and pooping.

I'm a network and systems administrator by profession. I've been using computers for 29 years, and I'm only 37 on Dec 2nd. I've been at the same job for 15 years, and computers come naturally to me. When I was a kid I was called a geek, a nerd, you name it. But, I didn't let it bother me. I continued doing what I loved, and I have a job doing what I love to do. Yeah, I make it look easy. I have decades of experience. If you had configured countless servers, databases, designed networks from scratch and upgraded them, you could make it look easy too.

That's what you do with your tools. You turn out tools that look like they came from a name-brand factory (with obsessive-compulsive QC), and they show it. I don't know how long you've been running machines, but you do it well. And you make me look like a complete noob. Because I am. Hopefully one day I'll be able to make tools that at least belong in the category of "nice", but that day isn't here yet. Functional, yes. But still seriously amateur.

Don't sweat the jealous idiots who give you crap. They ain't worth the effort to do anything but laugh at 'em. You don't have to prove a dang thing to them, because your work speaks for itself. Loudly. Extremely loudly.

You got an entire board of people behind you. Some on here make parts that are aerospace quality. Some of us barely know what a lathe *is*, and everywhere in-between. And every time I make a chip, I learn a tiny little bit. Each successful part is a little better than the last, and even the horribly wrong parts teach me something.

So smile, relax, and go make some chips. Twiddling handwheels is therapeutic as heck. :thumbsup2:

As for the people who try to run you down, don't sweat 'em. They're probably jealous that you make functional works of art, and all they can make is chips and chatter-marked scrap.

Pardon my crudity here for a moment....

Nobody pops out of their mother's hoo-ha a master machinist. Or a master of anything, except crying, suckling, and pooping.

I'm a network and systems administrator by profession. I've been using computers for 29 years, and I'm only 37 on Dec 2nd. I've been at the same job for 15 years, and computers come naturally to me. When I was a kid I was called a geek, a nerd, you name it. But, I didn't let it bother me. I continued doing what I loved, and I have a job doing what I love to do. Yeah, I make it look easy. I have decades of experience. If you had configured countless servers, databases, designed networks from scratch and upgraded them, you could make it look easy too.

That's what you do with your tools. You turn out tools that look like they came from a name-brand factory (with obsessive-compulsive QC), and they show it. I don't know how long you've been running machines, but you do it well. And you make me look like a complete noob. Because I am. Hopefully one day I'll be able to make tools that at least belong in the category of "nice", but that day isn't here yet. Functional, yes. But still seriously amateur.

Don't sweat the jealous idiots who give you crap. They ain't worth the effort to do anything but laugh at 'em. You don't have to prove a dang thing to them, because your work speaks for itself. Loudly. Extremely loudly.

You got an entire board of people behind you. Some on here make parts that are aerospace quality. Some of us barely know what a lathe *is*, and everywhere in-between. And every time I make a chip, I learn a tiny little bit. Each successful part is a little better than the last, and even the horribly wrong parts teach me something.

So smile, relax, and go make some chips. Twiddling handwheels is therapeutic as heck. :thumbsup2:

Mark, It is people like you that inspire newbie guys like me. I can honestly say when I see your work it shows that with some patience and creativity you can do almost anything. Seeing work like yours causes me to think about projects I can try, if I fail I probably still learned something valuable. I have a son that is pretty good at machining, he once asked me to help him out machining some parts for his employer. When I got there to help he told me I was about to get my PHD. I learned that night the difference between a machine operator and a machinist. I got to load parts on a really cool CNC mill then had to Push Here Dummy. I have a feeling that I would not care to do that job every day. The projects we do together that take thought are enjoyed no matter what the outcome. The projects you show us inspire us to go further. The guy who emailed you probably only has his PHD. Not making fun of anyone who actually has the schooling or experience to have the real thing(PHD). Keep up the good work. It also is a compliment if someone can't tell store bought from your work. :thumbsup2:

Went to the plans/print page, Think i saw most everything there but the zero-it, lol Its really no problem, i'm sure I can figure something out.

Here you go

hope you can see it. I made mine to fit my Last Word indicator . that is why there are no details on finishing that block. You make it fit your indicator. There are some tricks to making this successfully. If you are going to make one let me know and I will fill you in on what I learned the hard way.

hope you can see it. I made mine to fit my Last Word indicator . that is why there are no details on finishing that block. You make it fit your indicator. There are some tricks to making this successfully. If you are going to make one let me know and I will fill you in on what I learned the hard way. Mark Frazier

I think it is in the members projects or it is in the thread of the fellow who posted it here. there is a photo of it in use and how it is made.Mark,

I'd be proud to have any one of your shop made tools in my garage-shop.

Can I ask how does your vice alignment jig work?

Mike

Mark Frazier

- Joined

- Aug 27, 2014

- Messages

- 65

I really don't know what else to say,

Mark Frazier

Whew! Your photos are my to-do list! Thank you Mark!

CannonFodder

- Joined

- Aug 27, 2014

- Messages

- 65

I really don't know what else to say,

Mark Frazier

Whew, your photos are my to-do list!! Awesome work and thank you Mark.

CannonFodder

Whew, your photos are my to-do list!! Awesome work and thank you Mark.

CannonFodder

I think you posted the vise alignment tool, didn't you. thank you for that. that tool is a real time saver. I use it for more than the vise. I line up parts that clamp to the table with it too. Man, it will save hours on some projects.

:thumbzup3: Mark frazier