- Joined

- May 24, 2012

- Messages

- 395

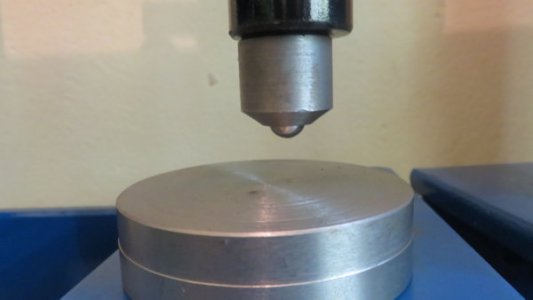

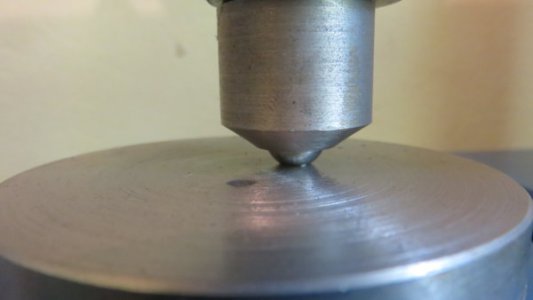

Had someone used a regular shop press plus a bearing ball to conduct a Brinell test?

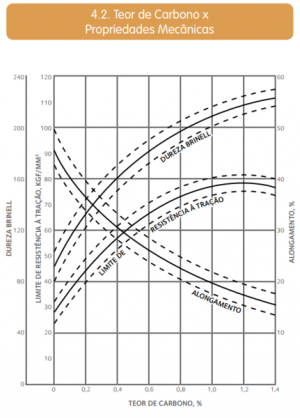

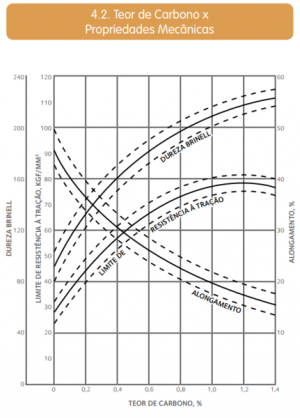

My goal is identify unknown steels and relate brinell hardness with ultimate strenght.

At 3tons, there much risk of ball bearing exploding?

https://me-mechanicalengineering.com/brinell-hardness-test/

My goal is identify unknown steels and relate brinell hardness with ultimate strenght.

At 3tons, there much risk of ball bearing exploding?

https://me-mechanicalengineering.com/brinell-hardness-test/