- Joined

- Oct 17, 2018

- Messages

- 922

I'm considering mounting a DRO on my Atlas Craftsman 101.07403 lathe.

I've seen a few threads on adding DRO's to lathes, but I'm posting here because I want to know if anyone has added a DRO set-up to this particular lathe. I have some ideas, but don't want to re-invent the wheel.

I could mount the Z (spindle axis) DRO along the back and mount the bracket holding the read head to the carriage somehow.

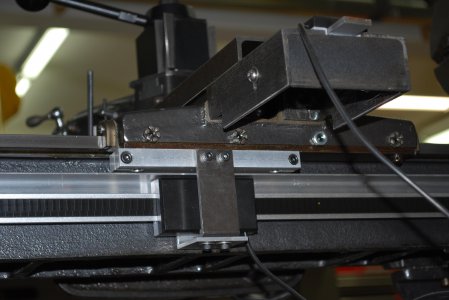

The cross-slide seems like the hardest place to add a DRO on these lathes because there are no flat/square surfaces that are big enough to easily mount anything. Here's a picture of the location I'm thinking I'd like to mount it, the right/tailstock side of the carriage.

If anyone has any pictures, I'd love to see them. Thanks!

I've seen a few threads on adding DRO's to lathes, but I'm posting here because I want to know if anyone has added a DRO set-up to this particular lathe. I have some ideas, but don't want to re-invent the wheel.

I could mount the Z (spindle axis) DRO along the back and mount the bracket holding the read head to the carriage somehow.

The cross-slide seems like the hardest place to add a DRO on these lathes because there are no flat/square surfaces that are big enough to easily mount anything. Here's a picture of the location I'm thinking I'd like to mount it, the right/tailstock side of the carriage.

If anyone has any pictures, I'd love to see them. Thanks!