-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us what you made with your Southbend lathe!

- Thread starter HMF

- Start date

- Joined

- Sep 23, 2010

- Messages

- 619

- Joined

- Sep 23, 2010

- Messages

- 619

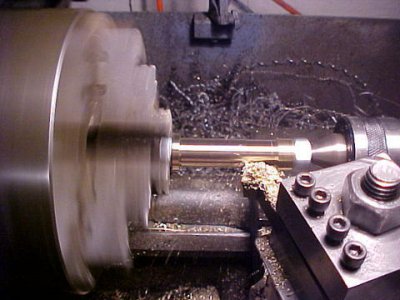

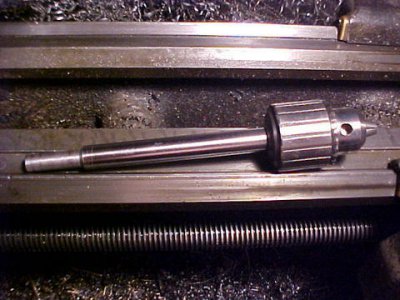

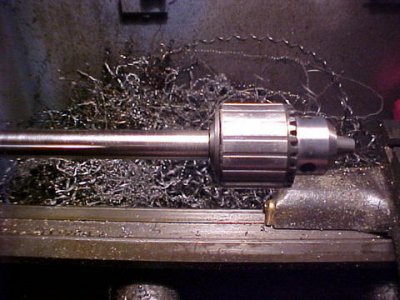

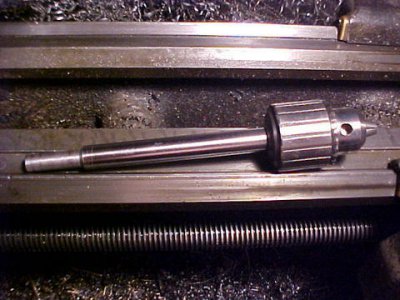

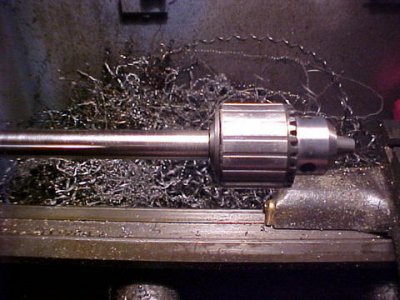

Here is a big nose center i made for turning 2" pipe and other large openings. I also use it for my die handle to get the die straight on short threads. It is just an arbor with 2 bearings on the one end and a #2MT turned on the other. Then the big cone just slides over the bearings and is held on with a sheetmetal cover...Bob

![63c2[1].jpg 63c2[1].jpg](https://www.hobby-machinist.com/data/attachments/1/1039-e0493b8b354eb1991842a96ec9e9a374.jpg)

![63c2[1].jpg 63c2[1].jpg](https://www.hobby-machinist.com/data/attachments/1/1039-e0493b8b354eb1991842a96ec9e9a374.jpg)

Last edited by a moderator:

- Joined

- Sep 23, 2010

- Messages

- 619

Here is a little alum knob i made for my computer speaker. It was my daughters Dell and the knob was missing and i got tired of turning that little stub. I used my cross slide hole driller to drill the #21 hole then tapped it 10-24. It even has a "chatter" finish on the fron for decoration. I have mastered that finish well...Bob

Last edited by a moderator:

- Joined

- Sep 22, 2010

- Messages

- 7,223

Bob,

That is a great idea and very practical!

I can really use one of those cross-slide hole drillers because once I take the part out of the chuck, I will never get it back

in the same way after drilling on the drill press.

Thanks for sharing that with us!

Best,

Nelson

That is a great idea and very practical!

I can really use one of those cross-slide hole drillers because once I take the part out of the chuck, I will never get it back

in the same way after drilling on the drill press.

Thanks for sharing that with us!

Best,

Nelson

- Joined

- Sep 23, 2010

- Messages

- 619

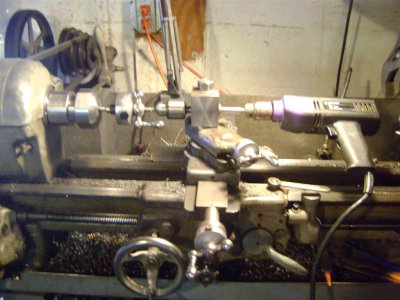

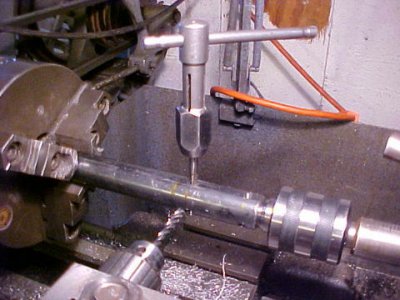

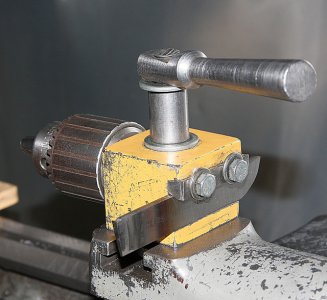

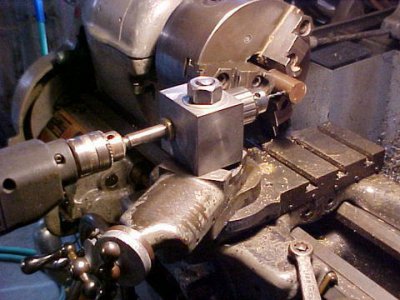

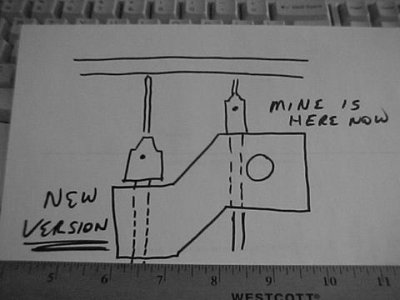

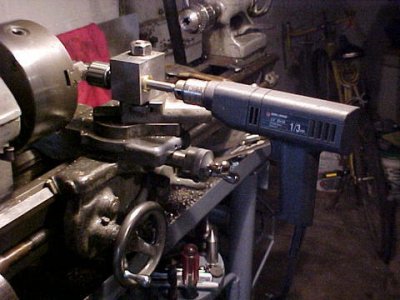

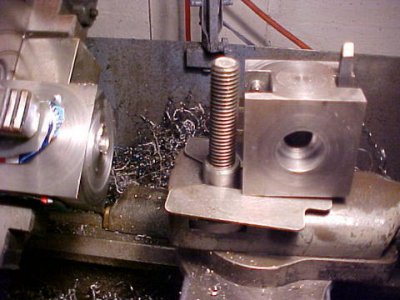

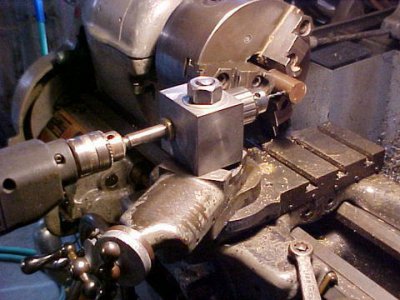

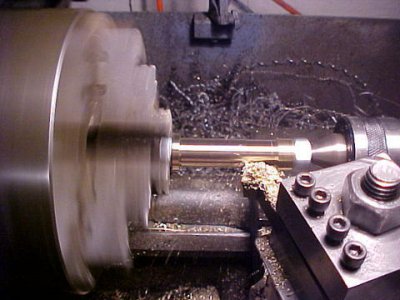

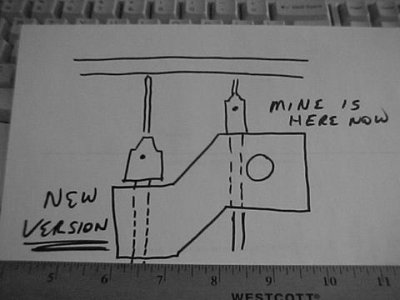

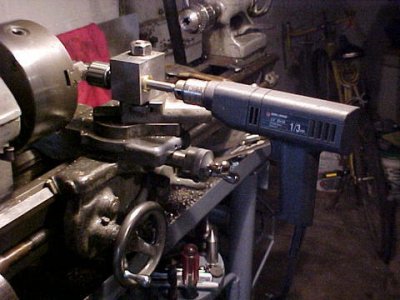

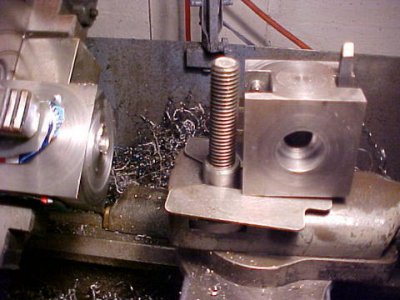

Here are some more pics when i was building the cross slide hole driller. Just build yours to suit. But my next one will be an offset block for cross drilling that way i can use longer drill bits. Mine is great for small drills and drilling towards the lathe chuck. I can also angle the drill block for crooked holes. That was my whole reason to make this work so i could do furnace tips from work that had holes drilled at goofey angles. Figured it would save a whole bunch of setup in a mill or drillpress...Bob

Last edited by a moderator:

- Joined

- Sep 23, 2010

- Messages

- 619

Re: Show us what you made with your lathe!

Just make sure you make the shaft and bronze bushing as tight as possable to keep shaft movement down. I drilled an oil hole on top of the block and fill it every now and then...Bob

Just make sure you make the shaft and bronze bushing as tight as possable to keep shaft movement down. I drilled an oil hole on top of the block and fill it every now and then...Bob