My stock selection is often Unkownium recyclium metals. Whatever is in the scrap bin that is big enough to accomodate the part I need to make.

Here is a picture of the dial indicator holder for the QCTP I made up. I used a chunk of steel, I believe it was labeled as T1 armour plate by the supplier that I had previously used to make up bearing knives for the press. I had two chunks left from the cutout and used one, the other is shown in the picture. Also used a chunk of 1/2" keystock and a few bolts out of the reclaimed bolt bin.

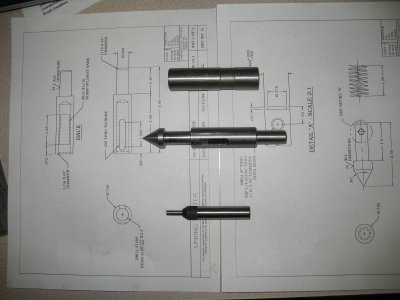

Spring centre was made from a scrap of metal shafting, I believe came out of an old 6 x 48 belt sander.

[quote author=wawoodman link=topic=692.msg7827#msg7827 date=1301270412]

Materials question:

What are the materials used in most of these projects, like Bob's cross slide drill attachment? I'm guessing steel, but how do you cut that offset block? With a bandsaw?

[/quote]

This would depend on what the raw stock looked like. a cast iron block could be used and cast to rough dimensions. A block of steel could be bandsawn, flame cut or just keep milling till the profile emerges. I personally would probably bandsaw as much extra material off until I got closer to the finished size before milling the final edges. Other that have a shaper, metal shaper, not wood shaper may use that to finish the block to size. Another route, although much slower would be to use a hacksaw and a file.

Walter