- Joined

- Dec 14, 2013

- Messages

- 167

gjmontll,

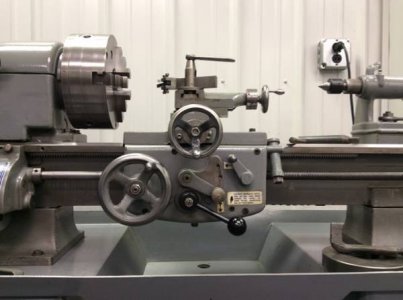

You're right, it is a forward/reverse switch and it does work. I read about the potential for the chuck to fly off the lathe when reversed so I keep it in forward and haven't messed with it other than checking to see if it works. I attached a picture for a better look. This lathe has a 1/2 horse motor with an Atlas nameplate on it so this forward/reverse switch may have been attached to the leg when and if the motor was changed. The on/off switch is on the headstock casting with a plate that has forward/off/reverse markings but only functions for turning the lathe on and off.

You're right, it is a forward/reverse switch and it does work. I read about the potential for the chuck to fly off the lathe when reversed so I keep it in forward and haven't messed with it other than checking to see if it works. I attached a picture for a better look. This lathe has a 1/2 horse motor with an Atlas nameplate on it so this forward/reverse switch may have been attached to the leg when and if the motor was changed. The on/off switch is on the headstock casting with a plate that has forward/off/reverse markings but only functions for turning the lathe on and off.

Last edited: