A

Alex

Forum Guest

Register Today

Here's 6 of mine ...

1. 1993 Bridgeport Series 1, 2hp vertical mill with an ABB VFD located in a rear-mounted electrical box controlled by my custom panel

2. 1929 Southbend 11x60 lathe with a Woods VFD controlled by my custom panel

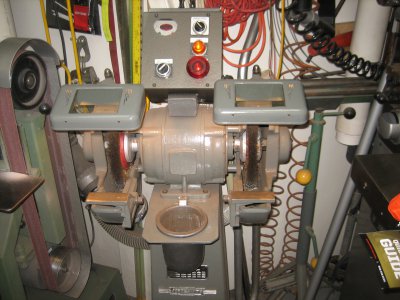

3. 1961 Ford-Smith 10" double arbor wire wheel with a Korean VFD controlled by my custom panel

4. 1998 Burr King 2x60 belt grinder with an Allen Bradley VFD controlled by my custom panel

5. 1996 FPS 3x89 backstand belt grinder with a Woods VFD

6. 2012 custom built multi buffer station with an Allen Bradley VFD hidden inside a 1960 vintage cast iron pedestal

Nightshift, where did you source your switches? The few I've found have been out of this world expensive ($120+ per switch) and I'm hopeful there is a more reasonable option out there.