- Joined

- Nov 22, 2010

- Messages

- 371

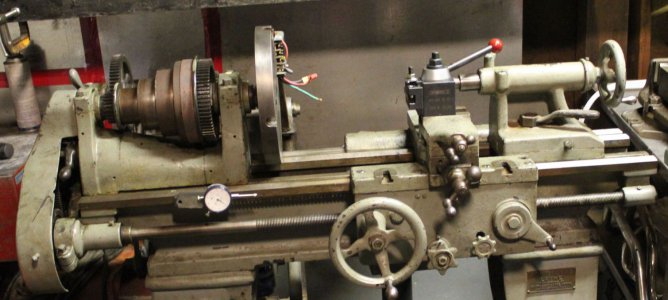

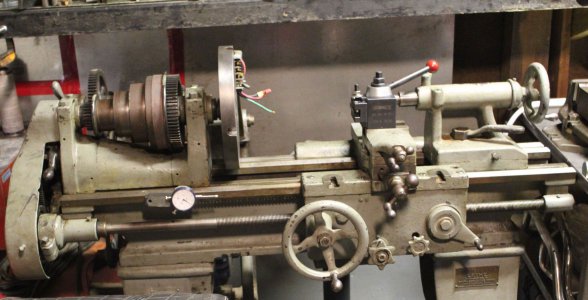

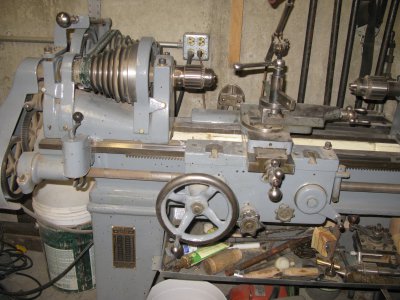

Here's my latest project completed and ready for market

its a 1944 SB 9" that was a model "B" and was converted to a Model "A" during the restoration.

The ways were so beautiful the Upgrade was deemed " necessary" It is light on tooling only a 5" 3 jaw self centering chuck, and a 6" independant 4 jaw chuck.... lantern tool post and Armstrong 1/4" bit holder. no rests dead center .but the condition of every part of the Lathe proper is fantastic.

All felts, gaskets and oil retainer plugs were replaced during assemply after complete paint stripping and repaint with rustoleum industrial repaint. its a " Blood Red"jewel

its a 1944 SB 9" that was a model "B" and was converted to a Model "A" during the restoration.

The ways were so beautiful the Upgrade was deemed " necessary" It is light on tooling only a 5" 3 jaw self centering chuck, and a 6" independant 4 jaw chuck.... lantern tool post and Armstrong 1/4" bit holder. no rests dead center .but the condition of every part of the Lathe proper is fantastic.

All felts, gaskets and oil retainer plugs were replaced during assemply after complete paint stripping and repaint with rustoleum industrial repaint. its a " Blood Red"jewel