-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your South Bend Lathe

- Thread starter HMF

- Start date

- Joined

- Nov 9, 2012

- Messages

- 10

- Joined

- Jan 22, 2011

- Messages

- 8,031

Well, I'll tell you guys something. I don't really have use for those machines in my shop, but I'd be proud to own one. Some of those are simply too pretty to use. Like just off the showroom floor. I can tell a lot of love and many, many hours of labor have been invested in them. They have the proper aesthetic appeal, and an aura of old age Industrialism about them that just isn't anywhere else. If my office was big enough, and when I do finally get to fully retire, maybe I'll hunt one down just for something to do and have one sitting by the desk.

Well, I'll tell you guys something. I don't really have use for those machines in my shop, but I'd be proud to own one. Some of those are simply too pretty to use. Like just off the showroom floor. I can tell a lot of love and many, many hours of labor have been invested in them. They have the proper aesthetic appeal, and an aura of old age Industrialism about them that just isn't anywhere else. If my office was big enough, and when I do finally get to fully retire, maybe I'll hunt one down just for something to do and have one sitting by the desk.

I use my many hours each week

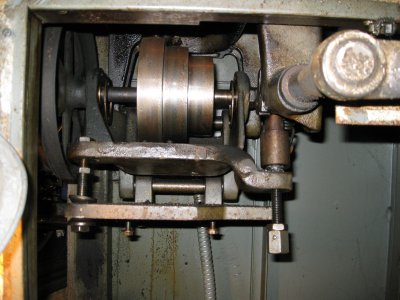

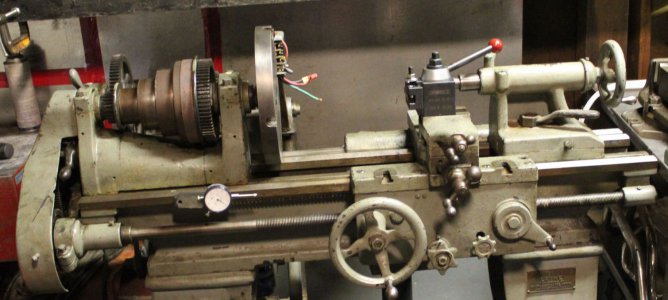

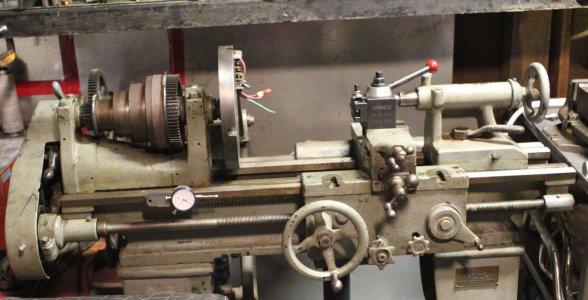

Have a 1958 Southbend 9A works well; am about to embark on a "rewick" and clean upView attachment 51109View attachment 51110View attachment 51111View attachment 51112