- Joined

- Jun 22, 2013

- Messages

- 8

Sandama,

Very nice rebuild. The bench and drawer are outstanding.

Thank you Sir,

I'm just trying to get close to what i've seeing here in this site, great machinery and great restorations

Sandama,

Very nice rebuild. The bench and drawer are outstanding.

here is my progress so far! taking a lil longer than what i wanted too, but had to slow down and build the bench and the drawer for it too.

I'm still waiting for the lead screw and i have to modify the apron to fit so i feel the headache coming soon.

a few posts before i showed the way i got it in case you all are curious.

I'm pretty happy with the way it is coming along! not bad for a jack of all trades master of none right..... LOL

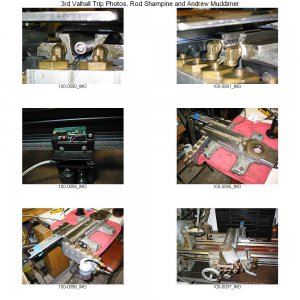

View attachment 56424View attachment 56425View attachment 56426View attachment 56427View attachment 56428View attachment 56429

sandama......

Nice work on the lathe and the Bench looks right at home! Custom fit is always nice. Good Job!

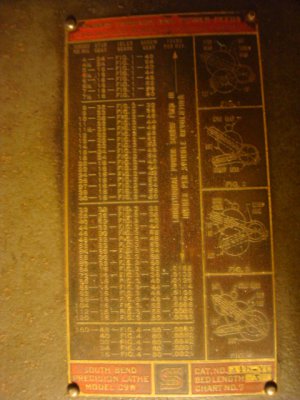

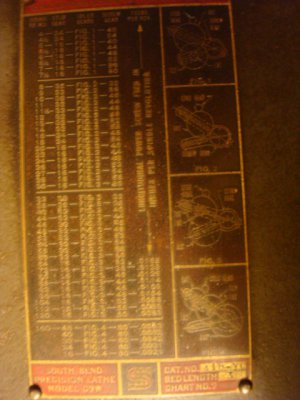

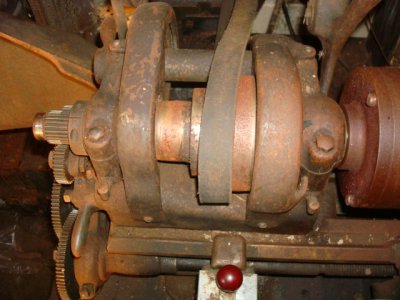

Well, after almost two decades of wanting to do it, I finally converted my D-Day South Bend to a D1-3 spindle this weekend. Of course now that I have a Hardinge, I'm selling the South Bend to a buddy of mine... at least he will get to enjoy it!

I hopped this old lathe up just about as far as is possible: VFD drive, two axis DRO and a DRO on the compound. I put pressure fed lubrication on the carriage and cross slide (one pulse of air= one shot of oil on every hole).

A REALLY nice upgrade if your lathe likes oil in the spindle pulley (which mine did): add a ball oiler so you can inject without having to take out that darn threaded plug!