- Joined

- May 14, 2013

- Messages

- 104

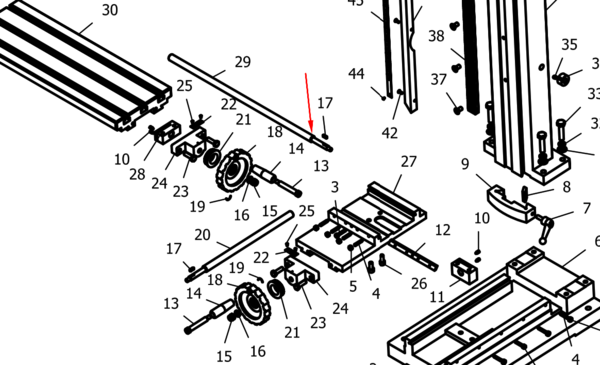

I'm working on a power feed, went to screw the X (long) axis feed screw back in from the other side, discovered there was a small lock washer kinda thing right at the transition from thread to spindle end (where the handle slides on). Had to forcefully remove it (verrrrrry carefully), and now I can thread the feed screw in from the other side.

However, I now need to replace that. No prob! Except it's not on any parts diagrams or lists anywhere... It kinda looks like its purpose was to prevent the feed screw from trying to pull itself too far in at the feed screw nut?

Like here's my machine: Parts diagram PDF

(they call it the Y axis)

The feed screw shoulder right before the thread has nothing in the parts diagram there. (see red arrow)

Anyways, I'm probably just going to fabricate something, but super curious why it was on my machine, but not in the diagrams. Even the LMS diagrams have nothing for any of the clones of this machine.

BTW, this is what I've done which required me to screw it in from the other side...in hindsight maybe not the best solution.

Why I'm asking this is that after reassembly, there is an enormous amount of backlash. (could also be that my modifications aren't allowing the handle nut to fully pull everything together) Is there a definitive guide to "eliminate backlash in a mini mill"?

However, I now need to replace that. No prob! Except it's not on any parts diagrams or lists anywhere... It kinda looks like its purpose was to prevent the feed screw from trying to pull itself too far in at the feed screw nut?

Like here's my machine: Parts diagram PDF

(they call it the Y axis)

The feed screw shoulder right before the thread has nothing in the parts diagram there. (see red arrow)

Anyways, I'm probably just going to fabricate something, but super curious why it was on my machine, but not in the diagrams. Even the LMS diagrams have nothing for any of the clones of this machine.

BTW, this is what I've done which required me to screw it in from the other side...in hindsight maybe not the best solution.

Why I'm asking this is that after reassembly, there is an enormous amount of backlash. (could also be that my modifications aren't allowing the handle nut to fully pull everything together) Is there a definitive guide to "eliminate backlash in a mini mill"?