H

Hukshawn

Forum Guest

Register Today

What’s the usual grit for a silicon carbide grinding wheel?

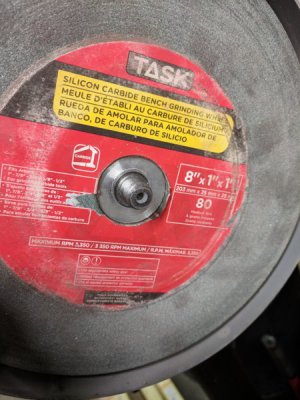

I have an 8” from princess auto (Harbor freight) and I have a seriously hard time grinding carbide. I understand it’s slow going, but we’re talking no going most of the time. I feel that wheel is too fine. It just rubs and polishes and gets the carbide part hhhott, then the wheel loads up. I could be standing there for an hour and not actually take any material off. Makes grinding profiles, or stats least changing the grind on a boring bar a total mess. I used to use a lot of green silicon carbide wheels at an old job, and we chewed through them like hot cakes and they ground carbide very quickly. We would go through 1 or 2 in a shift replacing carbide teeth in surgical needle holders. This wheel doesn’t act the same at all.

I have an 8” from princess auto (Harbor freight) and I have a seriously hard time grinding carbide. I understand it’s slow going, but we’re talking no going most of the time. I feel that wheel is too fine. It just rubs and polishes and gets the carbide part hhhott, then the wheel loads up. I could be standing there for an hour and not actually take any material off. Makes grinding profiles, or stats least changing the grind on a boring bar a total mess. I used to use a lot of green silicon carbide wheels at an old job, and we chewed through them like hot cakes and they ground carbide very quickly. We would go through 1 or 2 in a shift replacing carbide teeth in surgical needle holders. This wheel doesn’t act the same at all.