- Joined

- Jan 2, 2014

- Messages

- 8,852

Hi All,

I had a project a while ago where I needed some metal rings.

https://www.hobby-machinist.com/threads/the-duct-tape-catamaran.79401/post-680110

I made this ring roller for that job, but hadn't got around to taking pictures, writing it up and presenting it here.

Yesterday I needed to use it again to make a heavy band clamp for my exhaust system so I took the time to finally get some pictures.

Here's the vise:

and the original jaws:

Here are the replacement jaws made of 1" x 3" solid bar, some 1/2"-20 nuts and bolts, some ball bearings a big nut and chunk of steel shaft as the solid roller.

ring roller jaws installed on vise:

The rear roller is just a chunk of shaft with a big nut welded on top as a way to drive it with a wrench.

That big nut was bored out on the lathe so the head of the bolt and a washer would fit inside....it also gives clearance for a socket during assembly.

The nuts under the roller and the ball bearings are just jam nuts that are tightened against the bar to stop the bolts for turning while you're rolling.

Here's a couple more shots:

You can see that I countersunk the socket-head cap screw for the front jaw, but realized I did NOT need to for the back jaw as the front and rear rollers already overlap when the jaws are close together.

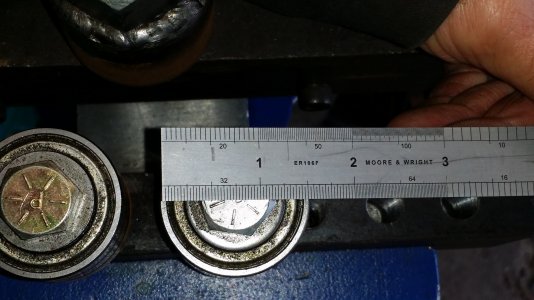

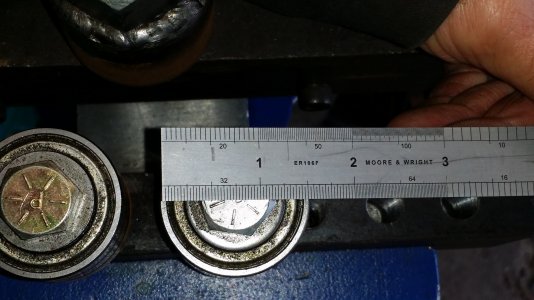

...and a few photos with a ruler to give rough size:

I'll continue with a few more photos in a couple minutes......

-brino

I had a project a while ago where I needed some metal rings.

https://www.hobby-machinist.com/threads/the-duct-tape-catamaran.79401/post-680110

I made this ring roller for that job, but hadn't got around to taking pictures, writing it up and presenting it here.

Yesterday I needed to use it again to make a heavy band clamp for my exhaust system so I took the time to finally get some pictures.

Here's the vise:

and the original jaws:

Here are the replacement jaws made of 1" x 3" solid bar, some 1/2"-20 nuts and bolts, some ball bearings a big nut and chunk of steel shaft as the solid roller.

ring roller jaws installed on vise:

The rear roller is just a chunk of shaft with a big nut welded on top as a way to drive it with a wrench.

That big nut was bored out on the lathe so the head of the bolt and a washer would fit inside....it also gives clearance for a socket during assembly.

The nuts under the roller and the ball bearings are just jam nuts that are tightened against the bar to stop the bolts for turning while you're rolling.

Here's a couple more shots:

You can see that I countersunk the socket-head cap screw for the front jaw, but realized I did NOT need to for the back jaw as the front and rear rollers already overlap when the jaws are close together.

...and a few photos with a ruler to give rough size:

I'll continue with a few more photos in a couple minutes......

-brino