- Joined

- Sep 9, 2014

- Messages

- 90

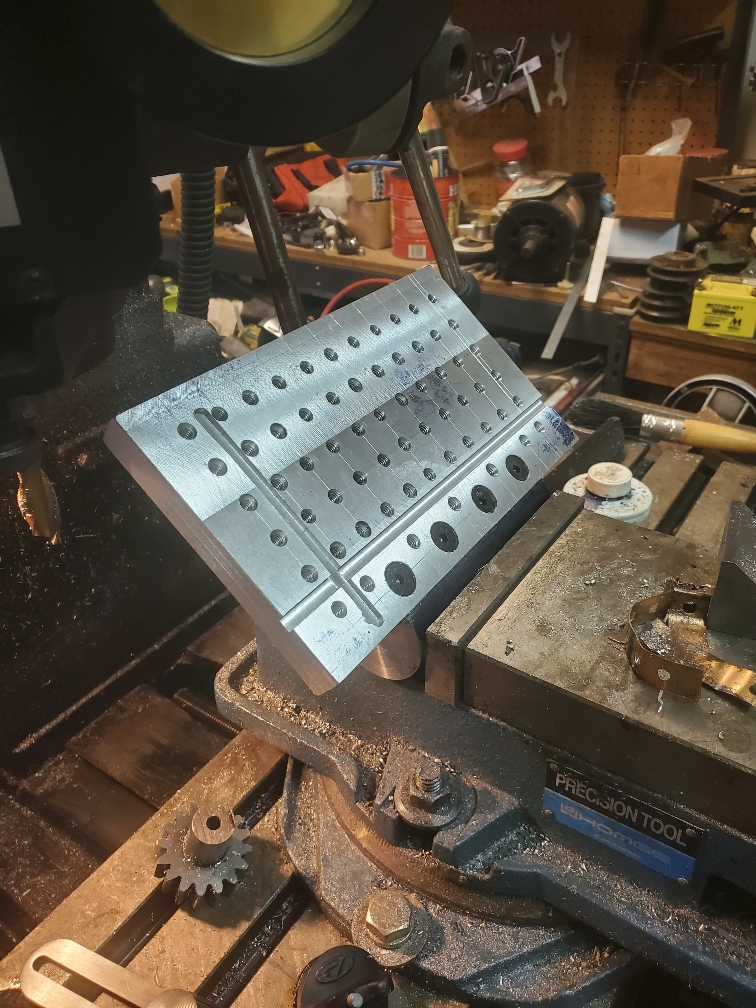

I would like for all of you guys who have built your angle plates to know that they are all beautiful works of art. I only wish I had the time to build some of the things I've seen you guys do.

Too many guns to fix or build. No time for my own fun. My wife keeps telling me I'm retired and I should take it easy. I retired from working for someone else. When you work for yourself, it hard to just quit. One day soon, I hope. Then I can play with my tools like you guys do.

Keep up the nice work and know it's appreciated,

Ron

Too many guns to fix or build. No time for my own fun. My wife keeps telling me I'm retired and I should take it easy. I retired from working for someone else. When you work for yourself, it hard to just quit. One day soon, I hope. Then I can play with my tools like you guys do.

Keep up the nice work and know it's appreciated,

Ron