- Joined

- Sep 15, 2017

- Messages

- 321

Hello all

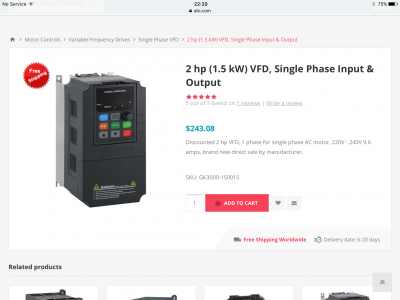

I have just purchased a mill it is running a single phase 220volt motor .Is there anyone familiar or had experience in using single phase in and single phase out VFDs as I have been looking online and there are a few suppliers of them now and seem to be slowly becoming more available

I know I could go single in 3 out and change the motor as I converted my lathe however if I can run the original motor of a single phase out VFD i would save on a motor and maybe an easier option for variable speed .

Any input appreciated

I have just purchased a mill it is running a single phase 220volt motor .Is there anyone familiar or had experience in using single phase in and single phase out VFDs as I have been looking online and there are a few suppliers of them now and seem to be slowly becoming more available

I know I could go single in 3 out and change the motor as I converted my lathe however if I can run the original motor of a single phase out VFD i would save on a motor and maybe an easier option for variable speed .

Any input appreciated