- Joined

- Dec 19, 2018

- Messages

- 129

Looks much better. The speed and feed I gave you is a .0007" per tooth chip load (based upon a 3 flute mill). If you try 1900 rpm and 3.5 ipm that works out to be .0006 . Try different chip loads and feel how the tool is cutting. Once you start to gain experience you will be able to "feel" on the table handwheels how the tool is cutting. You can start to feel when the tool is getting worn or getting clogged by feeling added resistance as you feed into your workpiece. You ideally want to mill to feed exactly the same throughout your entire cut. Good luck, keep at it.

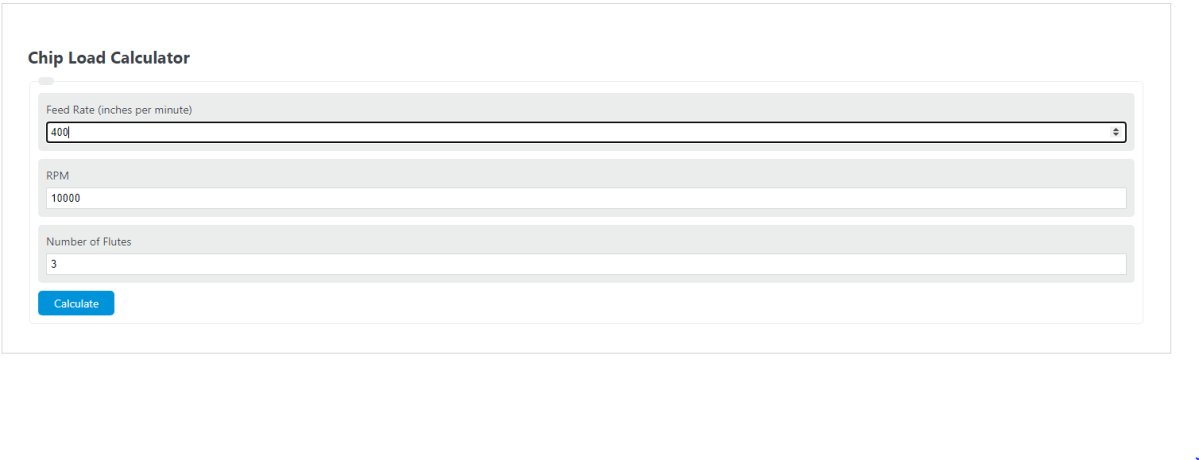

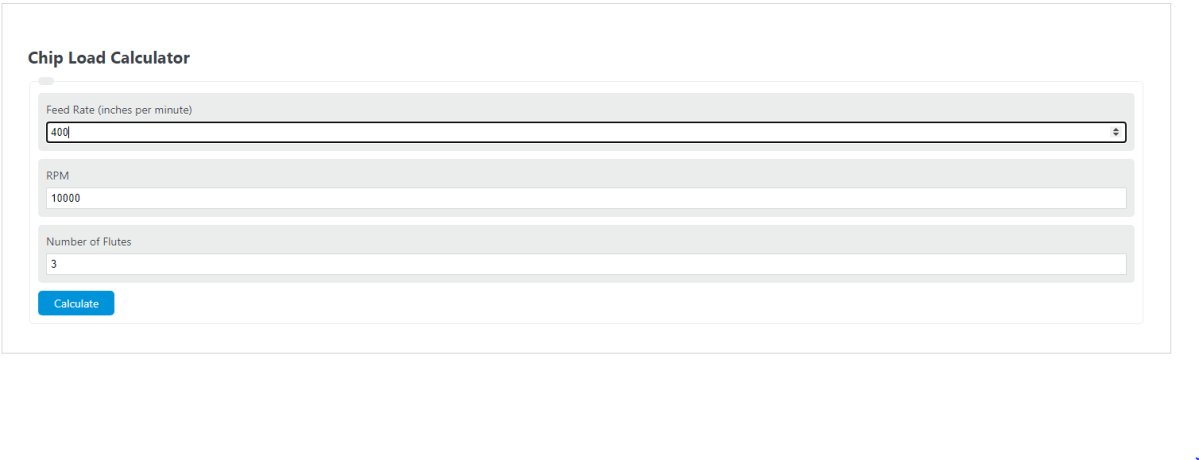

Simple chip load calculator :

calculator.academy

calculator.academy

Simple chip load calculator :

Chip Load Calculator - Calculator Academy

Enter the feed rate, RPM, and the number of flutes into the calculator to determine the chip load.

calculator.academy

calculator.academy