Fun times , I was playing around with my lathe, getting ready to do some LH thread cutting practice and 1st problem I only have 1 32 tooth gear and 2nd problem I was getting into a practice cut and out of no wear Some noises and the lead screw stopped. Broke a gear few teeth came off. So now its time to find gears.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Smithy CB 1220 XL gears

- Thread starter mac1911

- Start date

- Joined

- Dec 19, 2018

- Messages

- 130

Thats odd and concerning you broke gear teeth . Im hopeing you didnt experience some type of mechanical bind. Did you hear the motor struggle at any point ? As a rotating system safeguard my Grizz uses a aluminum pin that joins the transmission output shaft to lead screw coupler.Fun times , I was playing around with my lathe, getting ready to do some LH thread cutting practice and 1st problem I only have 1 32 tooth gear and 2nd problem I was getting into a practice cut and out of no wear Some noises and the lead screw stopped. Broke a gear few teeth came off. So now its time to find gears.

Im thinking a gear already had cracks , as it did not really have a “hard stop” type of incident.Thats odd and concerning you broke gear teeth . Im hopeing you didnt experience some type of mechanical bind. Did you hear the motor struggle at any point ? As a rotating system safeguard my Grizz uses a aluminum pin that joins the transmission output shaft to lead screw coupler.

It just made a noise clunk and from that point it was just making noise like a tooth is missing clink clunk .

The lead screw was in N

I later set it back up to the way I had it before. All seems well.

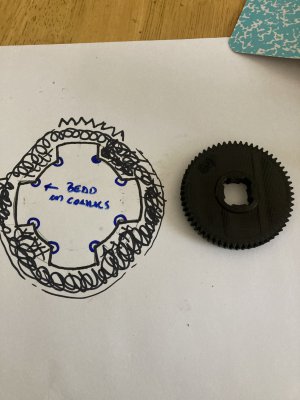

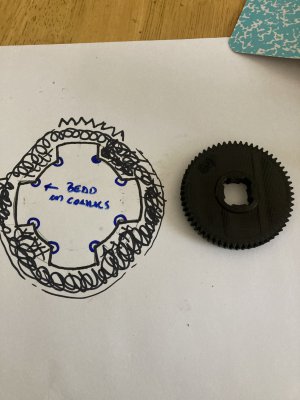

Recieved some test 3D gears for fit

The 4 spline hub seems to be a smithy thing but between my crude measuring capabilities and a friend with 3D printer and engineering skills he sent a test batch. Other than what I think is a printer issue they fit. Looks like the printer tip left a small bead at the corners of the splines. A few minutes with some sand paper and exacto knife they fit. Here is a crude drawing of the small issue.

The 4 spline hub seems to be a smithy thing but between my crude measuring capabilities and a friend with 3D printer and engineering skills he sent a test batch. Other than what I think is a printer issue they fit. Looks like the printer tip left a small bead at the corners of the splines. A few minutes with some sand paper and exacto knife they fit. Here is a crude drawing of the small issue.