By "polyester" I suppose that "mylar" is meant. Mylar became the standard for drawing stability rather than vellum paper, at least for the larger drawings that were produced at the Westinghouse Marine Division and other aerospace/defense companies where I was employed.

There was also a coated woven linen fiber medium that was very sturdy and superior to mylar for heat resistance but the coating could quickly be abraded away, especially with the electric erasers that became universal in the 'sixties. I recall that by the late 'sixties, linen was being phased out.

Linen media, as I recall, was used primarily for inked drawings while mylar could be used for both ink and pencil. The mylar drawing surface had a "tooth" - a roughened surface - so that graphite pencil lead would slightly abrade and imbed the particles that then constituted the drawing lines.

Linen media required that the surface first be treated using a fine powder called "Pounce" before inking. The pounce slightly roughened the smooth coating on the linen so that it absorbed the ink. (Without pounce, the inked lines would tend to "bead up" so continuous lines couldn't be produced.)

Old-timers may recall drafting pencil lead hardness classifications: for example, 5H was often used for construction lines, 4H for center lines and dimension lines and 2H for object lines and H for lettering. There was also a product consisting of fine particles of rubber erasing compound contained in a cloth bag but I don't recall what we called it.

The bag was coarsely woven so that the particles could be released as the bag was squeezed and manipulated over the drawing. The resulting fine particles were then lightly brushed over the surface of the pencil drawing with a drafting brush (another tool that has disappeared with the usage of CAD). The purpose was to absorb the fine dusting of pencil graphite that inevitably spread over the drawing surface, to keep the drawing cleaner.

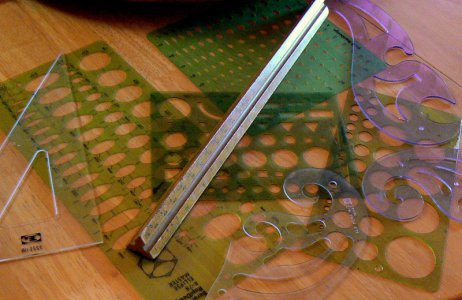

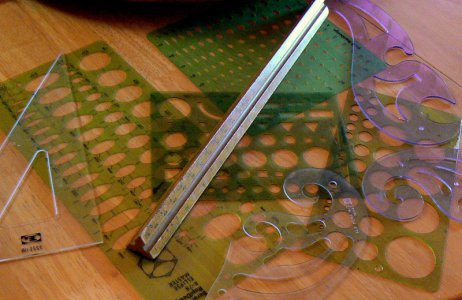

Man, does this thread bring back memories. Here are a few manual drafting tools that I still own and sometimes even use, LOL. There are also two Dietzgen compasses and a pair of dividers out in the shop that find occasional use. In the center of this photo is a triangular architects

scale. This one is special because it was first used by my Dad then passed on to me. The scale is approximately ninety years old.