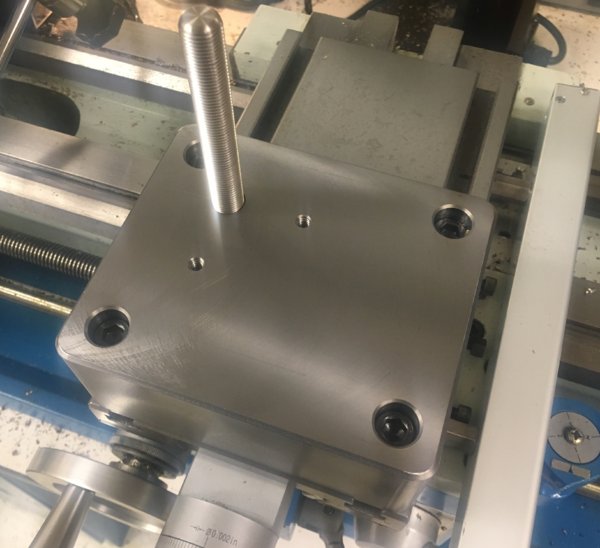

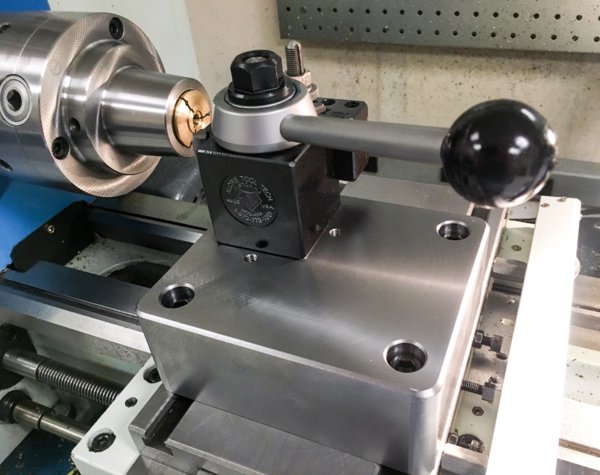

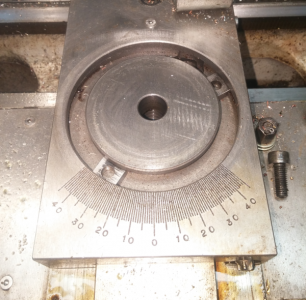

Decided to replace the compound slide on my PM1127 with a solid tool post mount for an Aloris AXA QCTP. Has virtually eliminated chatter (especially when parting off) and has allowed me to set tool offsets for each tool. I’m planning on using miteebite fixture clamps or something similar to prevent the tool post from rotating View attachment 260150View attachment 260153

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solid Tool Post Mount

- Thread starter MSD0

- Start date

- Joined

- Oct 18, 2016

- Messages

- 2,872

Nice job on the mount. I made something similar for my lathe recently and the improvement in rigidity was well worth the effort.

Last edited:

ThanksNice job on the mount. I made something similar for my lathe recently and the improvement in rigidity was worth the effort.

Thanks, yeah it’s a big improvement on smaller machines like the 1127.Nice job on the mount. I made something similar for my lathe recently and the improvement in rigidity was worth the effort.

Edit- I still need to try knurling to see how that goes. With the compound, there was a lot of deflection.

Last edited:

- Joined

- Dec 6, 2012

- Messages

- 2,677

One of the guru machinist (no sarcasm intended) videos recently showed similar.

So that I understand, please confirm that the miteebite fixture clamps will thread into the two threaded holes on the top of the riser.

I'm excited that you are getting better cuts.

Daryl

MN

So that I understand, please confirm that the miteebite fixture clamps will thread into the two threaded holes on the top of the riser.

I'm excited that you are getting better cuts.

Daryl

MN

I still need to order the fixture clamps, but I used the offset specified by the manufacturer. If for some reason that doesn’t work, I can always machine a flat on the opposite side of the clamp.One of the guru machinist (no sarcasm intended) videos recently showed similar.

So that I understand, please confirm that the miteebite fixture clamps will thread into the two threaded holes on the top of the riser.

I'm excited that you are getting better cuts.

Daryl

MN

The thickness is basically equal to the distance from the cross slide to the top of the compound.Was the thickness chosen for a specific reason? I'm sure thicker is better to a point, I'm just not sure what that point would be.

- Joined

- Dec 27, 2014

- Messages

- 4,056

I'm pleased to see the T slots in the cross slide, the manufacture recognizes that we like to make our own tooling blocks.

- Joined

- Apr 28, 2014

- Messages

- 3,590

Use a clamp type knurler. Much better and easier than a 'bumper'.Thanks, yeah it’s a big improvement on smaller machines like the 1127.

Edit- I still need to try knurling to see how that goes. With the compound, there was a lot of deflection.

- EDIT -

RobRenz' video -=- LINK -=-

Need to think about doing this on mine. Since I need to redo the T-Nuts, maybe do up (4) pcs to hold down the block.

Last edited: