- Joined

- Dec 19, 2018

- Messages

- 130

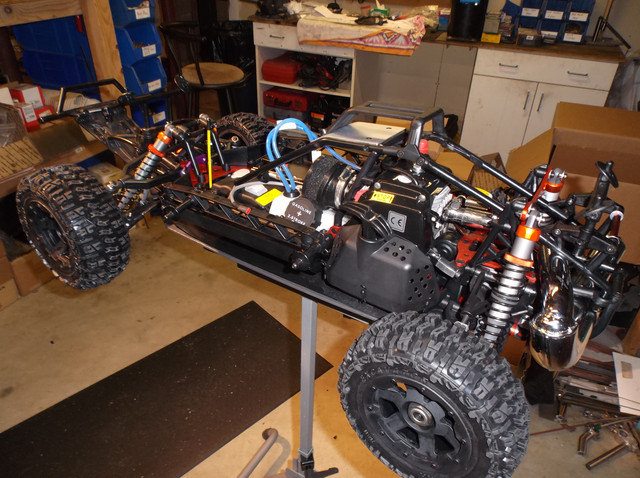

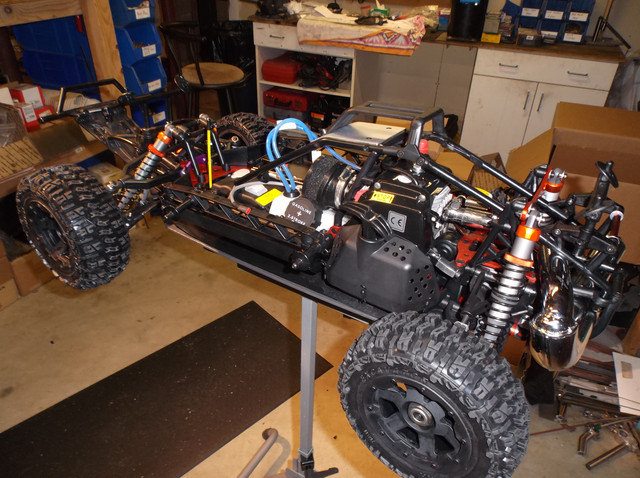

Bottom line absolutely LOVE this mill. I enjoy some pretty intricate hobbies such as vintage motorcycles, guns and 1/5 scale gas RC models. Over the past couple months my mill has proven to be an absolute problem solver with respect to machining widgets and repairing broken components that I potentially alternately would have had to thrown out in the trash. It also helps when you work for a machine shop where you get scraps of aluminum and used solid carbide tooling for free ! My most recent mill task calling was modifying many cheap plastic components with alloy on my 1/5 gas Baja RC model. As long as you keep your DOC light and you have sharp tooling the 4190 does a very nice job on aluminum. My favorite facing tool is an old Kennemetal 3" indexable insert shell mill and i'm just using one insert instead of all 5. I also experimented with the high speed gear set and it's a great solution when I needed to run small 1/8" endmills. The powerfeed is inconsistent as far as initial engagement feedrate but i've learned how to compensate for the speed variances by starting the power feed well off my workpiece and allowing about 4 seconds for the system to settle down into a consistent feed. Being able to monitor the feedrate within the DRO is a very nice option. I was not sure if I would be able to power tap aluminum but after some experience with the mill i'm having no problems power tapping without the need for a spindle reversing setup. I chuck up a tap tight , set the rpm's to about 100 rpm's and just maintain light downward assistive pressure on the z axis handwheel , and keep my finger on the stop button if i'm tapping a blind hole and just stop well before bottoming by watching the dro's Z depth. The brushless motor has adequate torque to tap up to M10 in aluminum at very slow speeds. Here's a pic of my 1/5 scale gas RC this project was a lot of gratification modifying with the help of my mill: