- Joined

- Jan 13, 2022

- Messages

- 4

Hello, Jeff Dreibus (owner of The Old Carb Doctor) here.

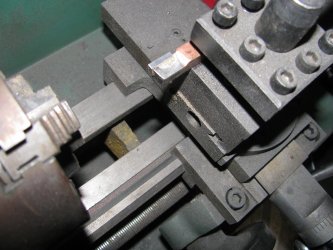

I have a Grizzly G8688 mini-lathe which I bought second-hand and have used for a few years to turn-down a particular type of brass carburetor needle. I now need some new C6 AR6 cutters (see photo). The cutters bearing this number (which came with it) seem to work pretty well, though I am always open to suggestions. They also read "Made in China", but I would prefer a source for U.S.-made cutters if possible (and yes, I know that the machine itself came from China).

As you have probably surmised by now, I am not really a machinist. My other "machine tools" consist of a belt sander, a hand-held drill and a Dremel. So: looking at the photo, please let me know if I do not have the cutter installed properly; that is how the lathe came to me with the cutter installed. All helpful tips are appreciated.

Thank you.

Jeff

I have a Grizzly G8688 mini-lathe which I bought second-hand and have used for a few years to turn-down a particular type of brass carburetor needle. I now need some new C6 AR6 cutters (see photo). The cutters bearing this number (which came with it) seem to work pretty well, though I am always open to suggestions. They also read "Made in China", but I would prefer a source for U.S.-made cutters if possible (and yes, I know that the machine itself came from China).

As you have probably surmised by now, I am not really a machinist. My other "machine tools" consist of a belt sander, a hand-held drill and a Dremel. So: looking at the photo, please let me know if I do not have the cutter installed properly; that is how the lathe came to me with the cutter installed. All helpful tips are appreciated.

Thank you.

Jeff