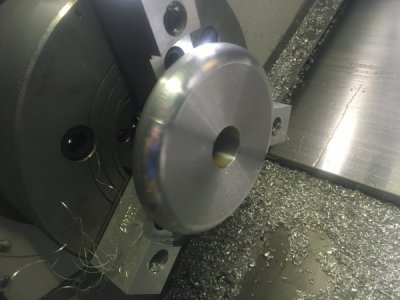

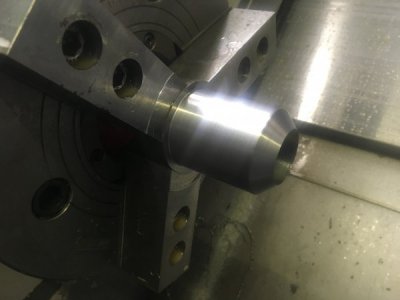

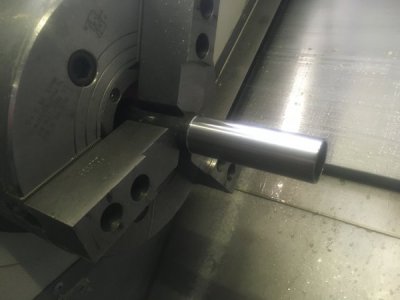

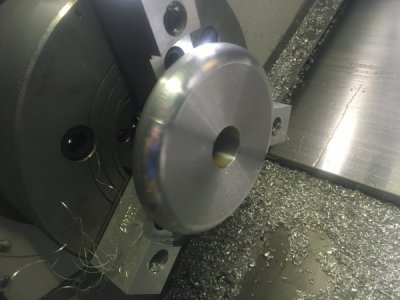

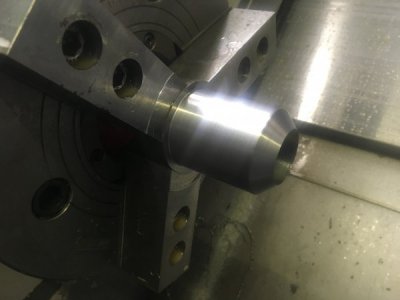

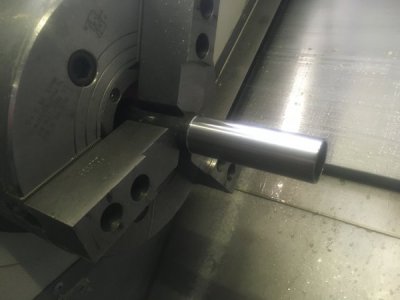

I needed a 5C draw tube for a SB16 at the school. I watched ebay for a while but a few weeks ago finally decided to just build one. I ordered some DOM, a thrust bearing, and balance came from the scrap bin. I modeled it loosely after the Clausing draw tube. I figured a few of you may be interested in the steps/build. I cranked this out on a Saturday morning at work on the cnc. My students did get the chance to drill and tap the set screws.