- Joined

- May 26, 2015

- Messages

- 756

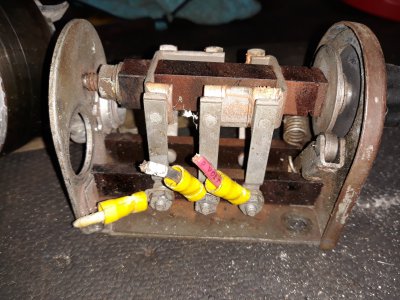

Did a trade for this South Bend 9 C, "I think", lathe. It's still riding around with me in the back of my covered truck until I can find a spot for it to rest. LoL Looks to be in pretty good shape but is missing the change gears and the small pulley on the motor, which is a GE 1/2 hp with 1/2" shaft. Trying to find a proper flat belt pulley but have only seen 5/8" bore pulleys. If I can't find something to fit I'll bore the pulley out and press a bussing in. I've started a tear down of the motor and the counter shaft assembly for cleaning and painting. Might be restoration sacrilege but I'm thinking of painting it blue to match my circa 1935 drill press as pictured.

Attachments

Last edited: