-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

South Bend 9A restoration happening w/pics!!

- Thread starter LX Kid

- Start date

- Joined

- May 26, 2015

- Messages

- 746

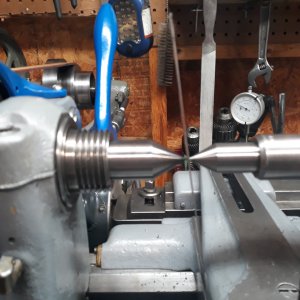

I went back and did an re-alignment of the tailstock and now found it was over shimmed. I removed/replaced shims and now I'm reading good on my cuts. Saw this quick alignment trick on YouBoob and seemed to work out good for me. Steel rule between the two dead centers. The pic is before re-shimming. ThanksI wouldn't count on that bed having less wear than yours, good chance it has more, plus your saddle ways will not match the new bed. Work with what you have and tweak the leveling to determine if it suits your needs.

Attachments

Last edited:

- Joined

- May 26, 2015

- Messages

- 746

I'm kinda in a "hmmm, I wonder" mode now. I realigned / re-shimmed my tailstock and now it's cutting quite good. Don't know if I should buy the lathe bed or not. It' been brought to my attention that my saddle wear might not fit well with the new lathe bed.Maybe we can set up a pony express. I can get it to Crawfordsville, Indiana. If someone else is local to there and could advance it closer to Tampa and so on, we might be able to make it low cost.

- Joined

- Oct 16, 2019

- Messages

- 6,570

I went back and did an re-alignment of the tailstock and now found it was over shimmed. I removed/replaced shims and now I'm reading good on my cuts. Saw this quick alignment trick on YouBoob and seemed to work out good for me. Steel rule between the two dead centers. Thanks

Not sure if that’s the after alignment pic but I think the tail stock is higher than the spindle.

Sent from my iPhone using Tapatalk

- Joined

- Jul 13, 2017

- Messages

- 635

LX, are you laundering drug money?

- Joined

- May 26, 2015

- Messages

- 746

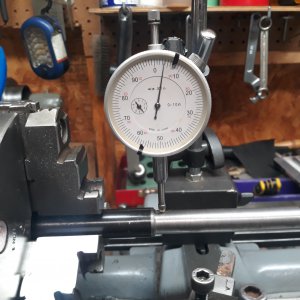

The pic was before I re-shimmed. I just did another test cut and "now" I'm off again! Checked with mic and am .007" off and with a dial gage I'm off by .004" between ends. I zeroed on the tailstock end.Not sure if that’s the after alignment pic but I think the tail stock is higher than the spindle.

Sent from my iPhone using Tapatalk

- Joined

- Jul 13, 2017

- Messages

- 635

What does your other, better test indicator show?

I thought this one was giving errant readings?

I thought this one was giving errant readings?