South Bend loves those as they are easy.

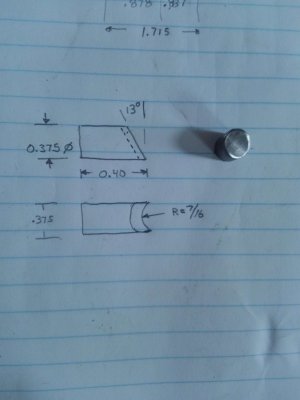

Simply assemble the parts, drill a hole and insert a pin.

Pay attention and you may see they are not accurate, some at different angles and such odd things.

But it does the intended task with a lot less work than cutting matching keyway

Sent from my SM-G781V using Tapatalk

Simply assemble the parts, drill a hole and insert a pin.

Pay attention and you may see they are not accurate, some at different angles and such odd things.

But it does the intended task with a lot less work than cutting matching keyway

Sent from my SM-G781V using Tapatalk