M

Mister Ed

Forum Guest

Register Today

I have had a SB shaper for a couple years now. I only use it once in a while when I need to make something flat. I want to change that, so recently I have been doing a bunch of reading through some old literature. I had always wondered about the cutting speeds on the shaper and really had an "aha moment" with the relationship of strokes/min and stroke length ... as they relate to cutting speed.

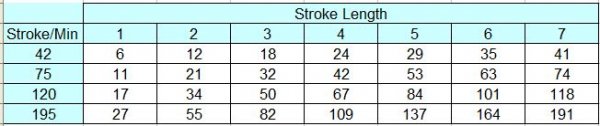

So, I made up the following chart and laminated it to keep at the shaper. The center section should be avg surface feet per minute, left section are the 4 different SB belt settings, and the top is stroke length in inches.

Hopefully this helps someone else. Its funny that they really do not talk much about this in their literature.

So, I made up the following chart and laminated it to keep at the shaper. The center section should be avg surface feet per minute, left section are the 4 different SB belt settings, and the top is stroke length in inches.

Hopefully this helps someone else. Its funny that they really do not talk much about this in their literature.

) and dwell time again 260° to 270°.

) and dwell time again 260° to 270°.