1946 Southbend 9" Model A Restoration

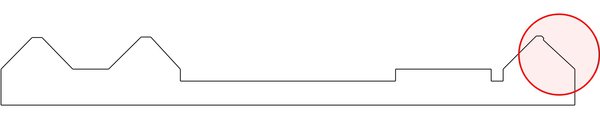

I'm looking at another Southbend, this one a 9 x 48 with quick change gears, and original cabinet/stand. I'm still waiting on a serial number, but he says the bed is a little worn near the head. It seems pretty obvious that we wouldn't ever want ANY deviation in the ways, but what I'm wondering is considering the filler products available, and repair techniques like scraping, how much wear would be considered too much to deal with? I have zero problem picking up a little bit of a project, especially at this price, I just don't want to wind up searching for a replacement bed because it was un-repairable.

Changed title from "Southbend 9 x 48 - How worn is too worn?" to "1946 Southbend 9" Model A Restoration".

I'm looking at another Southbend, this one a 9 x 48 with quick change gears, and original cabinet/stand. I'm still waiting on a serial number, but he says the bed is a little worn near the head. It seems pretty obvious that we wouldn't ever want ANY deviation in the ways, but what I'm wondering is considering the filler products available, and repair techniques like scraping, how much wear would be considered too much to deal with? I have zero problem picking up a little bit of a project, especially at this price, I just don't want to wind up searching for a replacement bed because it was un-repairable.

Changed title from "Southbend 9 x 48 - How worn is too worn?" to "1946 Southbend 9" Model A Restoration".

Last edited: