- Joined

- Feb 17, 2013

- Messages

- 4,406

Over the past month or so I've bought a set of ER32 collets, plus various chucks to fit my milling machines and lathes. I also bought a nice 4-point collet nut wrench from Shars. What I did not anticipate needing was a spanner for the MT3 and R8 collet chucks. Both of them have flats on the body behind the nut. The flats on the R8 are 40mm (1.575") wide and those on the MT3 are ~1.406" (35.75mm?)

I searched all the "usual suspects" on the interweb for suitable wrenches and the results were disappointing. I did find a few 40mm wrenches in the $20 price range, but nothing near the 1.406" size. I was about to try "rolling my own" from 2" steel bar. But on a fortuitous trip to Home Depot I found a "Slip & Lock Nut Wrench" on closeout - normally about $12, on sale for just over $6.

OK. The wrench looked like a crude (large grain) sand casting, no secondary machining except for grinding off the gates, then chrome plated. It had a draft angle of about 10º all over, including the jaw faces. And the knurled adjustmnt screw had at least 1/2 turn of slop.

On the plus side, there was a wing nut to lock in whatever size was set, and once set, the movable jaw did not wiggle or spread. The jaws were also nicely parallel. So I figured I could make a worthy tool out of it, and even if not, the price was right.

I started by removing the 1/4-20 wing nut and carriage bolt. The groove in the movable jaw that the carriage bolt rides in was pretty wide - wide enough for a 5/16" carriage bolt! The cast hole in the fixed jaw was nearly large enough to clear the shank of the bolt. A quick hit with a drill gave the required clearance (without even using up all the draft around the hole.)

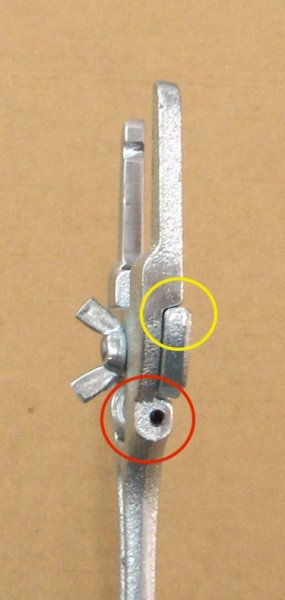

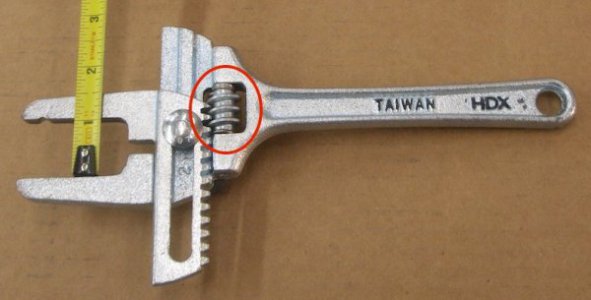

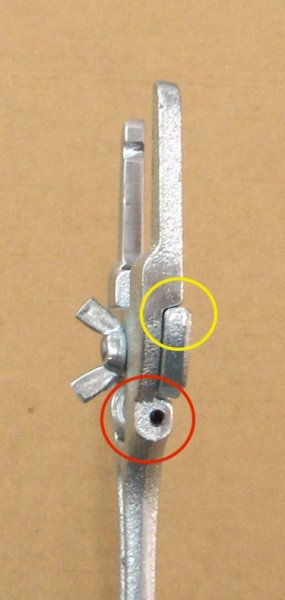

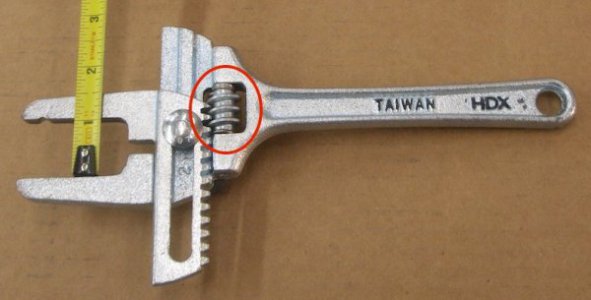

I next locked the jaws at about 40mm, added a couple of Kant Twists for good measure. Milled the faces of both jaws square and parallel, as shown in the first photo. Next I drilled into the fixed jaw opposite where the adjuster axle pin was pressed in. After drift punching the pin out I went back to the mill and took off the draft around the adjuster opening. When replacing the axle pin I added washers on both sides of the adjuster to remove the excess slop. The second photo shows the drilled hole (red outline) and also gives a good view of the draft angle of the castings (yellow outline).

The last three photos show how well the wrench fits the MT3 collet chuck, plus the maximum and minimum jaw openings. The third photo gives a good view of the washers added on either side of the adjuster (red outline). Note that I'd used a Sharpie to highlight the lettering on the casting.

Home Depot has discontinued this wrench and replaced it with one that uses a Nylock nut instead of a wing nut - no longer tightenable without tools! Price is $11.97:

https://www.homedepot.com/p/Husky-Adjustable-Plumbers-Wrench-16PL0134/304217578

Fortunately, the "original" wrench is still available from several sources if you want to adapt one like I did -

Lowes ($12.98):

https://www.lowes.com/pd/BrassCraft-3-in-Adjustable-Wrench/999903667

Ace ($13.99):

https://www.acehardware.com/departments/plumbing/plumbing-tools/plumbing-wrenches/43917

Amazon ($15.63):

https://www.amazon.com/Adjustable-Wrench-Removing-Tightening-Drainage/dp/B0000CBJG8

Menards ($9.99):

https://www.menards.com/main/plumbi...nut-wrench-3-max/sp-12315/p-1444421467918.htm

It's also available from General Tools - their #190.

I've looked at all of these in as much detail as I could find. Other than not having "HDX" cast into one side of the handle, they appear to be identical to mine.

I searched all the "usual suspects" on the interweb for suitable wrenches and the results were disappointing. I did find a few 40mm wrenches in the $20 price range, but nothing near the 1.406" size. I was about to try "rolling my own" from 2" steel bar. But on a fortuitous trip to Home Depot I found a "Slip & Lock Nut Wrench" on closeout - normally about $12, on sale for just over $6.

OK. The wrench looked like a crude (large grain) sand casting, no secondary machining except for grinding off the gates, then chrome plated. It had a draft angle of about 10º all over, including the jaw faces. And the knurled adjustmnt screw had at least 1/2 turn of slop.

On the plus side, there was a wing nut to lock in whatever size was set, and once set, the movable jaw did not wiggle or spread. The jaws were also nicely parallel. So I figured I could make a worthy tool out of it, and even if not, the price was right.

I started by removing the 1/4-20 wing nut and carriage bolt. The groove in the movable jaw that the carriage bolt rides in was pretty wide - wide enough for a 5/16" carriage bolt! The cast hole in the fixed jaw was nearly large enough to clear the shank of the bolt. A quick hit with a drill gave the required clearance (without even using up all the draft around the hole.)

I next locked the jaws at about 40mm, added a couple of Kant Twists for good measure. Milled the faces of both jaws square and parallel, as shown in the first photo. Next I drilled into the fixed jaw opposite where the adjuster axle pin was pressed in. After drift punching the pin out I went back to the mill and took off the draft around the adjuster opening. When replacing the axle pin I added washers on both sides of the adjuster to remove the excess slop. The second photo shows the drilled hole (red outline) and also gives a good view of the draft angle of the castings (yellow outline).

The last three photos show how well the wrench fits the MT3 collet chuck, plus the maximum and minimum jaw openings. The third photo gives a good view of the washers added on either side of the adjuster (red outline). Note that I'd used a Sharpie to highlight the lettering on the casting.

Home Depot has discontinued this wrench and replaced it with one that uses a Nylock nut instead of a wing nut - no longer tightenable without tools! Price is $11.97:

https://www.homedepot.com/p/Husky-Adjustable-Plumbers-Wrench-16PL0134/304217578

Fortunately, the "original" wrench is still available from several sources if you want to adapt one like I did -

Lowes ($12.98):

https://www.lowes.com/pd/BrassCraft-3-in-Adjustable-Wrench/999903667

Ace ($13.99):

https://www.acehardware.com/departments/plumbing/plumbing-tools/plumbing-wrenches/43917

Amazon ($15.63):

https://www.amazon.com/Adjustable-Wrench-Removing-Tightening-Drainage/dp/B0000CBJG8

Menards ($9.99):

https://www.menards.com/main/plumbi...nut-wrench-3-max/sp-12315/p-1444421467918.htm

It's also available from General Tools - their #190.

I've looked at all of these in as much detail as I could find. Other than not having "HDX" cast into one side of the handle, they appear to be identical to mine.