-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Speed reducer

- Thread starter mickri

- Start date

- Joined

- Dec 22, 2014

- Messages

- 201

My Jet uses a belt drive. I like the fact that it can slip if something jams in the cut. It does not slip in normal use. Just some thing to keep in mind. Could there be a problem with the belt?

Is it a metal cutting Jet with the auxiliary gear box? If so, it is using gears in the secondary drive. If no gearbox, it has relatively large diameter pulleys for proper "V-Belt Wrap"

Belts work fine at higher speeds and with enough "wrap" on the pulleys.

With a 50-1 gear reduction we are talking 39rpm at the output of the reducer with enormous torque. And there is limited space in my application for big pulleys to get adequate "V-belt wrap". AND, cutting metal of any thickness requires huge force against the blade. This all adds up to unacceptable slippage.

This is why belts can be used for the primary drive, but gears or chains take over from there.

- Joined

- Dec 22, 2014

- Messages

- 201

BTW....This is a good one:

"Adventure is just bad planning. "

But I like:

"The only difference between an Ordeal and an Adventure.....is your attitude!"

"Adventure is just bad planning. "

But I like:

"The only difference between an Ordeal and an Adventure.....is your attitude!"

- Joined

- Oct 31, 2016

- Messages

- 2,643

I have been using the band saw to cut the tubing for the headers that I am making. It is really slow going. I have purchased a 3" pulley to replace the current 7" pulley. Should get it in a couple of days. That will give me a better range of speeds to try. Also thinking about getting a wider 1/2" blade. The blades that I have are 1/4". Great for cutting a tight radius but probably not so good for making straight cuts.

I have been using the Vintage Machinery speed calculator for awhile. It is great to quickly see how different pulley sizes and reducers affect the fpm of the blade.

I have been using the Vintage Machinery speed calculator for awhile. It is great to quickly see how different pulley sizes and reducers affect the fpm of the blade.

- Joined

- Mar 3, 2013

- Messages

- 1,448

- Joined

- Dec 22, 2014

- Messages

- 201

I have purchased a 3" pulley to replace the current 7" pulley.

I think you are going to run into the same situation I did with such a small diameter pulley. Not enough belt wrap and you might have slippage. And if you tighten it up to try and alleviate the slippage, the bearing will have a short life. Let us know how it works out.

- Joined

- Mar 25, 2013

- Messages

- 4,614

It is a metal cutting Jet. It has a gearbox attached to the motor. The gearbox output drives a 3 stepped pulley. I usually run in on the slowest step so I have a 4" pulley driving about a 12" pulley. If it jams, it slips on the 4" pulley. It never slips in normal use.

I don't know if that info helps you. Certainly nothing wrong with your plan!

Robert

I don't know if that info helps you. Certainly nothing wrong with your plan!

Robert

- Joined

- Dec 22, 2014

- Messages

- 201

Thanks Robert! That 4" to 12" gets you just about enough wrap......I bet on the 6" pully there is much less slip. The more belt to pulley surface area the better....There is one of those JET Metal/Wood bandsaws available near me but he is asking $1000.....Brand new they are around $1500.....Nice saw!

- Joined

- Oct 31, 2016

- Messages

- 2,643

Picked up a belt today. Can't tell any difference in how the saw cuts with a quick test. Too cold in the garage today to do any more. I'll try again after the current cold front passes through and things warm up a bit.

- Joined

- Oct 31, 2016

- Messages

- 2,643

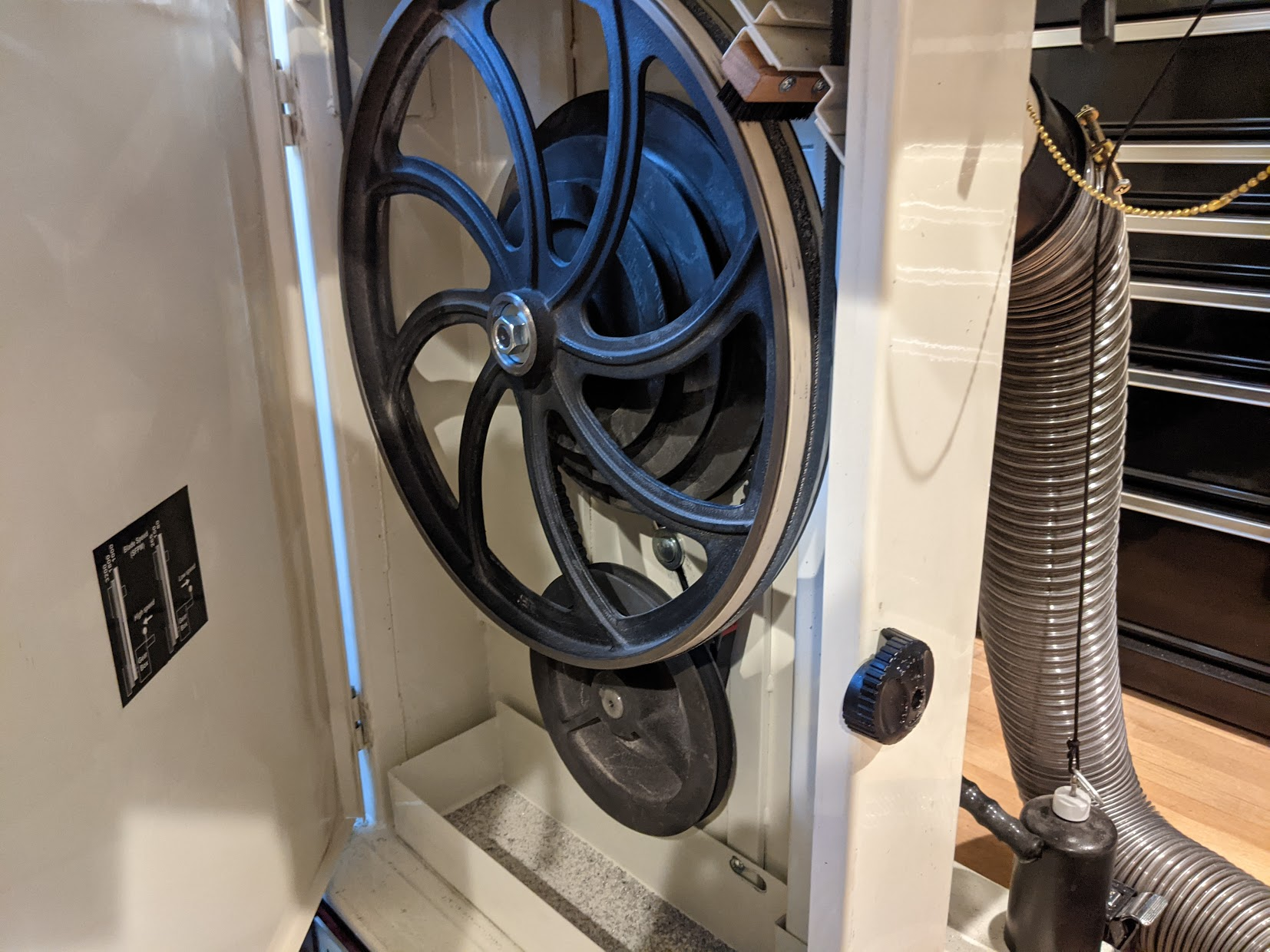

Been trying different things to try to get the saw to cut better. I discovered that the weight of the reducer and motor were not sufficient to keep the belt tight. Now I know this sounds weird but I discovered that if I put one foot on the pivot board that the motor and reducer are on the extra pressure kept the belt tighter and the saw worked better. I also found a 4.5" pulley in the spare parts box that came with my lathe.

Kind of awkward to balance on one foot with the other foot on the pivot board while trying to use the saw. So I added a tension screw.

Real easy to adjust the tension. Push down on the pivot board to get the belt tension I want and then tighten the nut. With the new found 4.5" pulley I put the 7" pulley back on the saw with the 4.5" pulley on the reducer. This gives 129 SFPM which is close to the 133 SFPM on my horizontal band saw. The horizontal saw slices through anything I cut. First test on the band saw and it cut though a piece of sheet metal like a hot knife slicing through butter. What a difference from before. I'll have to try some thicker steel to see how that goes.

Kind of awkward to balance on one foot with the other foot on the pivot board while trying to use the saw. So I added a tension screw.

Real easy to adjust the tension. Push down on the pivot board to get the belt tension I want and then tighten the nut. With the new found 4.5" pulley I put the 7" pulley back on the saw with the 4.5" pulley on the reducer. This gives 129 SFPM which is close to the 133 SFPM on my horizontal band saw. The horizontal saw slices through anything I cut. First test on the band saw and it cut though a piece of sheet metal like a hot knife slicing through butter. What a difference from before. I'll have to try some thicker steel to see how that goes.